Hi,

We are using DRV8353 (DRV8353RHRGZR to be exact) to drive the gates of the MOSFETs in a three-phase inverter used to drive a BLDC motor. We set the driver in "Synchronous 1xPWM Mode" which is the recommended mode of operation for the control of three-phase BLDC motors. However, we believe that the commutation table (Table-3 in the datasheet) for this operation mode is incorrect. We believe that the generated magnetic field vector according to the rotor position (hall sensor inputs) is not placed at the correct angle with respect to the rotor position. We expect that the angle between the rotor magnetic field vector and the created stator magnetic field vector should change between 120 degrees to 60 degrees (six step operation). In this way, we maximize the torque output per ampere (MTPA) by keeping the angle between the two magnetic field vectors at and around 90 degrees (torque is proportional with the sinus of the angle between these two vectors). However, for the commutation table which is provided in your datasheet (Table-3), for one direction (INHC=0) this angle varies between 60 degrees to 0 degrees and for the other direction (INHC=1) it varies between 120 degrees to 60 degrees. This, in turn, creates a no-load speed difference for two direction of rotations. In one direction, the motor speeds beyond its specified no-load speed for the given bus voltage, and in the other direction it is not able to reach its no-load speed. This, we believe, is because of the above mentioned angle difference between the two magnetic field vectors. In one direction, it weakens the magnetic field of the permanent magnets on the rotor, which in turn increases the no-load speed (field-weakening action). In the other direction, it, in contrast, strengthen the magnetic field of the rotor, which reduces the no-load speed of the motor since the generated back emf voltage is higher for the same speed. We observed that case in our setup. When we use the gate driver in the "Synchronous 1xPWM Mode", with the closed loop current controller implementation, the motor speeds up beyond its no-load speed specified in its datasheet for the given voltage, and for the other direction the motor is unable to reach its no-load speed. Furthermore, the motor is buzzing and vibrating anormally for the both direction of rotations.

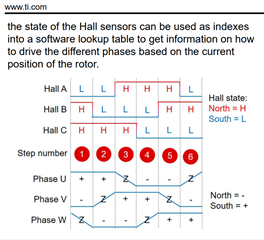

After making those observations and inferences, we also tried the other swithing scheme that we believe the correct way of commutation. I shared the commutation table that we implemented below.

According to this commutation table, you let the current flow through the motor phases such that the angle between the rotor magnetic field and stator magnetic field changes between 120 degrees to 60 degrees for each hall sensors combination and for both direction of operations. When we applied the voltage to the motor according to this commutation table, the motor reached the specified no-load speed in the datasheet for both direction of rotations. Furthermore, we didn't observe the vigorous buzzing and vibrating action from the motor anymore. It started operating smoothly and more silently. Also, when we search through the internet, the most common commutation table is the one I shared in the above image. Therefore, we believe the commutation table (Table-3) for the "Synchronous 1xPWM Mode" shared in your datasheet might be incorrect or improper for the BLDC applications.