I'm having trouble reliably driving a DC stepper motor with the DRV8811. I should start out by saying that I'm very new to DC stepper control, and only know what I've picked up during this project over the last few weeks.

My current control scheme utilizes 1/8 step micro-stepping at 12VDC drive voltage, and an imposed current limit of about 0.4A (PWM controlled via the 8811). Synchronous rectification is disabled, and it's currently set up in "slow decay" mode. The application rotates a slightly asymmetrical load at a fixed rate (about 60RPMs), for extended periods of time.

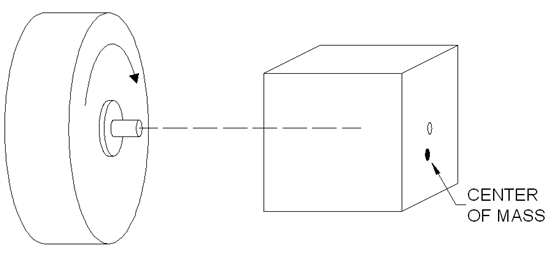

Figure 1: Motor Example with General Load Condition

The only issues I experience are during start-up, in particular orientations. I am not 100% convinced that there is a correlation to the physical orientation of the load, as much as the position of the center of mass when power is removed from the motor. Occasionally, on power-up, the motor will stall for a second or two, shake somewhat violently (for a 4 in-oz motor), and occasionally begins to rotate in the opposite direction.

I have tried several "start-up" routines, at the suggestion of a colleague, which entail starting the motor in a locked position, starting the motor at lower RPMs and increasing the speed gradually (over a half-rotation or so), or some variation/combination of the two. I have had success in limiting the frequency of occurrences with these routines, but they still do occur.

Power is an issue in my application as well, so I've reduced the drive current to as little as I possibly can. I have noticed, though, that increasing the current and/or voltage to the motor does not necessarily improve performance. In some instances, it exaggerates the issue I'm experiencing.

From the small amounts of playing around I've done, there does seem to be some relation to the stopped position of the rotor, and whether or not it came to a rest in a particular position. If, in a test condition, I locked the rotor by having the control software hold the rotor in one location, then remove power, the motor never stalls or rotates backwards. If power is removed without any pre-condition, however, the motor typically shutters a little during every power up, and occasionally rotates in the opposite direction.

I'm fairly confident this is user/control error, and hopefully there's a fairly easy fix. If anyone has any suggestions, I'd be very grateful for the help.