Other Parts Discussed in Thread: TM4C1294NCPDT

Sir.,

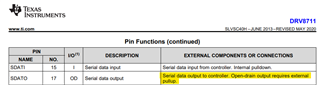

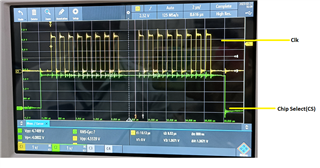

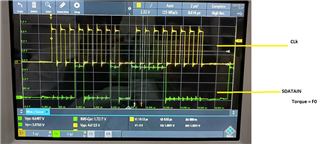

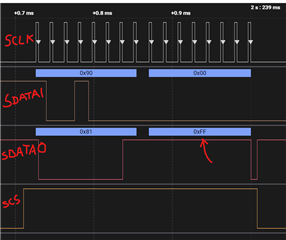

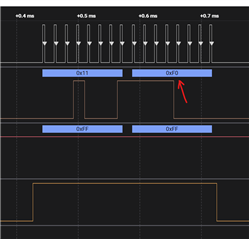

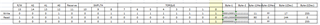

I apologize for the late reply. This query is the continuity for DRV8711: DRV8711 Stepper Drive Reg Read Issue.

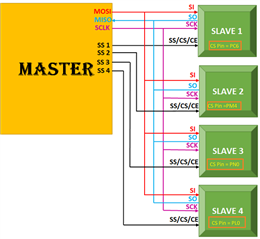

And the last question you asked , Each device has it's own dedicated chip select (CS) signal. Is the correct CS signal is used to read to the desired driver?

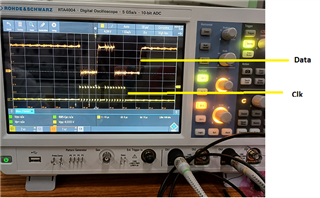

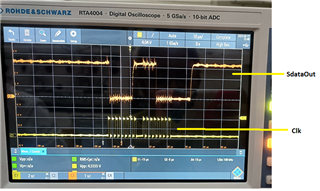

Yes Each device has its own dedicated CS signal. But read will be done on 5th attempt only. Kindly resolve this issue as soon as possible.