Other Parts Discussed in Thread: DRV8145-Q1

Hi team,

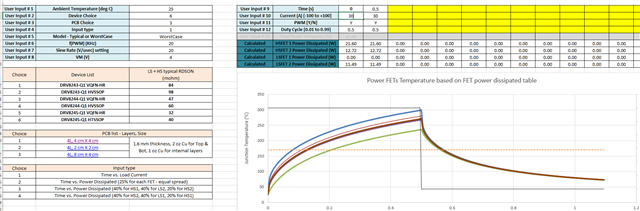

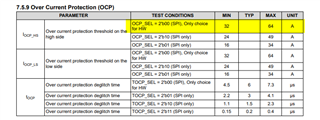

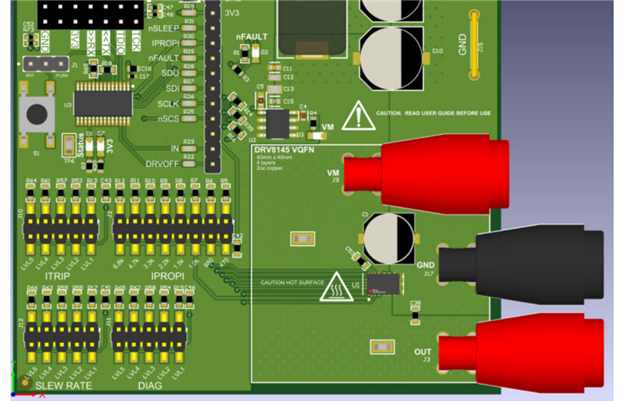

What is the locked rotor current of DRV8245-Q1? If locked rotor current is 30A, lasting 500ms, what is the cooling solution and how large is the area of the cooling plate? Is there anything else about cooling design should be aware of?