Dear E2E Team,

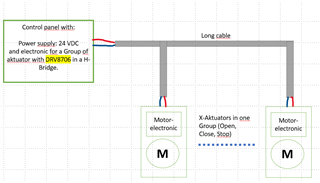

my question is about the H-Bridge driver DRV8701S-Q1. We need a control where one low-side MOSFET is driven while the other 3 MOSFETS of the H-Bridge are switched to high impedance. For our control panels we need this state for line monitoring.

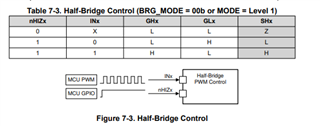

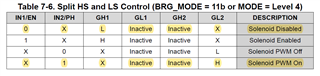

In the data sheet drv8701-q1.pdf on page 22 chapter 7.3.3.3 Split HS and Solenoid Control a mode is described where I can imagine that the control works.

According to the table I would use the following states:

Thus the high-side MOSFET GH1 has a high impedance and the low-side MOSFET GL2 has a low impedance (switched on).

Question: What does the status Inactive mean for GL1 and GH2? What happens to the MOSFETS connected in an H-bridge to GL1 and GH2?

Best regards

Frank Mueller

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.