Hi team,

Here's an issue from the customer may need your help:

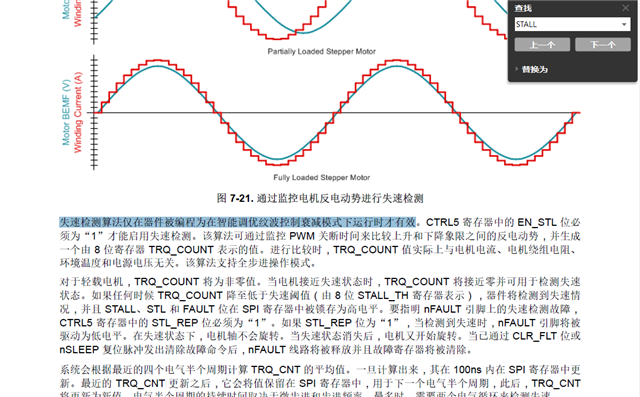

When driving the Nidec motor MSRPC20B09, coil disconnection, stall, and missing steps will happen. And as per the manual, "The stall detection algorithm is only valid if the device is programd to operate in smart tune ripple control decay mode. "(on page 36 of Chinese manual, could you please help check the correspond manual in English?)

However, during implementation, after setting to decay mode, the motor is unplugged and the chip (DRV8889) cannot detect.

Could you please help check this case? Thanks.

Best Regards,

Cherry