Hello,

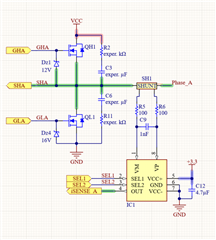

Check the H-bridge schematic bellow:

I'm going to use inline current sensing method to control a BLDC motor, using the DRV8353 driver.

So I need a suggestion for a suitable current sensor which capabilities are related to:

- Vcm >= 60V (desirable)

- Bidiretional (needed)

- Zero-Drift (desirable)

- Programmable-Gain

- Bandwidth for max gain > 100kHz (needed)

Note that.: I need a resolution of current not lower than 10mA DC for the max gain, so for a 12bit uC, I will ideally need a max gain of more than 100 considering a 1mOhms shunt resistor (consider also the max value for the shunt resistor is 2.5mOhm). For the min gain, a 12bit uC must measure a max current of at least 80A DC.

A nearly good solution is to use an INA225, but its Vcm is way lower than expected and I also don't know if this chip can handle a mA range. So, please anwer the questions:

1. Could you please indicate other products that fit in the specifications above?

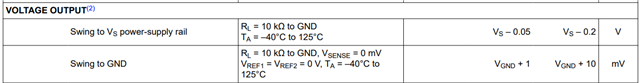

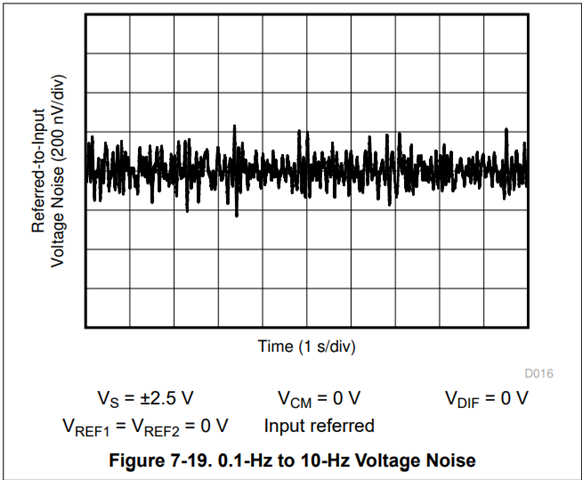

2. Can you show the analysis you do to garantee the selected chip is capable of measuring a 10mA current? (show the analysis for the INA225)

3. In the iten above, please indicate the parameters in the datasheet that make possible to measure the 1mA range.