Hello ,

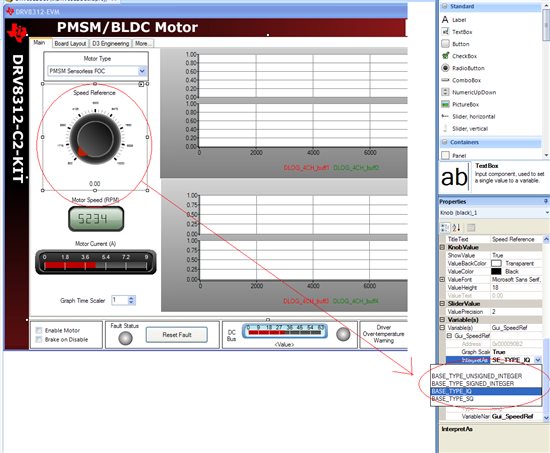

I am working with DRV8312-C2-Kit (just started).

We are going to make some test application for motor, by using other motor with its driver as dinamic load.

In order to receive some useful data for comparison, we need to collect data from the driver.

Is it possible to collect data about:

1. hall sensors,

2. current

3. to set turn direction

4. to set motion profile - such as, move at "x" speed, then increase for "y" time, then stop and again with cycles - is it possible to define?

if it is possible, can you please recommend some guide?

thank you very much,

have a great day

Yulya