Hi team,

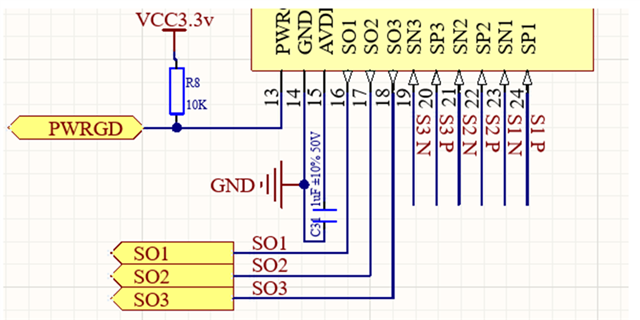

Motor drive scheme: Stm32f401+dvr8305, dvr8305 peripheral circuit is built according to 8.2 typical application of datasheet. Vcc=3.3V, PVDD=12v (operating from adjustable power supply).

The dvr8305 is driven using the stm32 monolithic chip, using the motor drive strategy of St Corporation. Previously there was a problem at startup, the motor would stop at the start of the open loop phase, the nfault pin would go low, customer guess it was due to PVDD undervoltage. This issue is resolved after modifying PVDD_UV_PWRGD (0xB bit2). The PVDD undervoltage is still present at start-up and the motor can operate in the initial open loop phase but will stop when closed loop is reached.

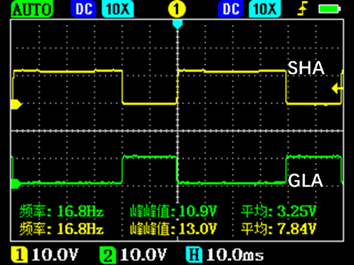

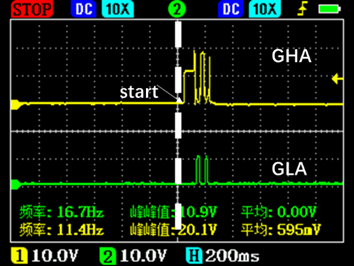

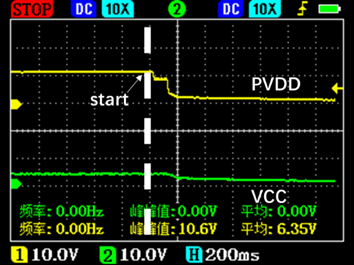

So the customer designed a 6-step control program to drive the motor start-stop. The motor is found to be slow and hot. Here are the oscilloscope measurements: (The oscilloscope has only 2 channels, only 2 waveforms can be displayed, so only information about motor a is measured)

DRV8305-phase A input pin signal

DRV8305-Phase A Output Pin (Motor not connected)

DRV8305-Phase A output pins and some zoomed-in view (connecting motor)

DRV8305-Phase A Voltage Measurement (Channel 1) with Motor connected

DRV8305-operating voltage PVDD (was 12v, but buck to 4.3V) and Vcc (connected to motor)

It seems like the measured waveform is not the same as the normal waveform, could you help check this case? Thanks.

Best Regards,

Cherry