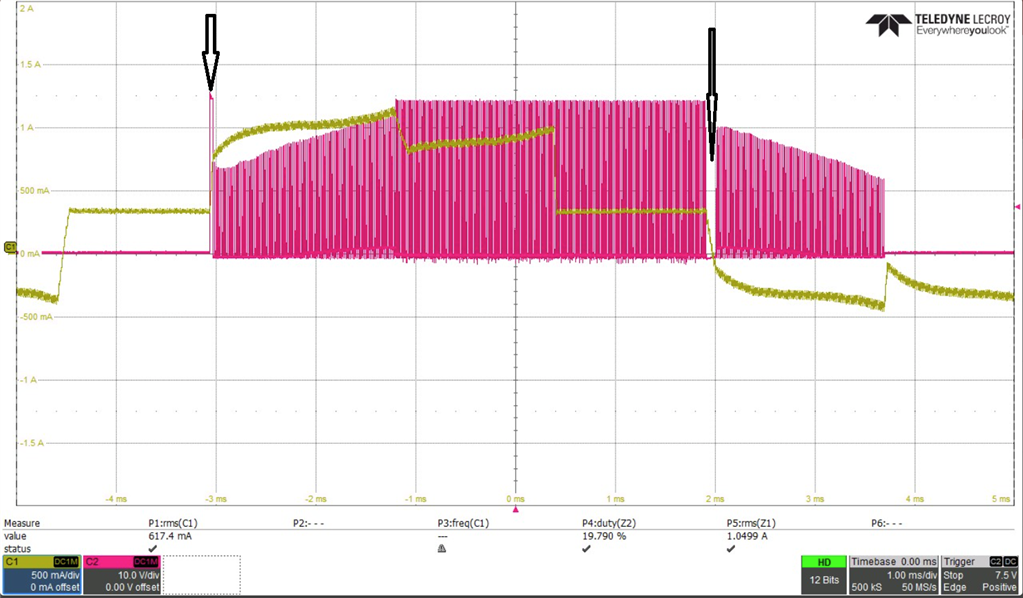

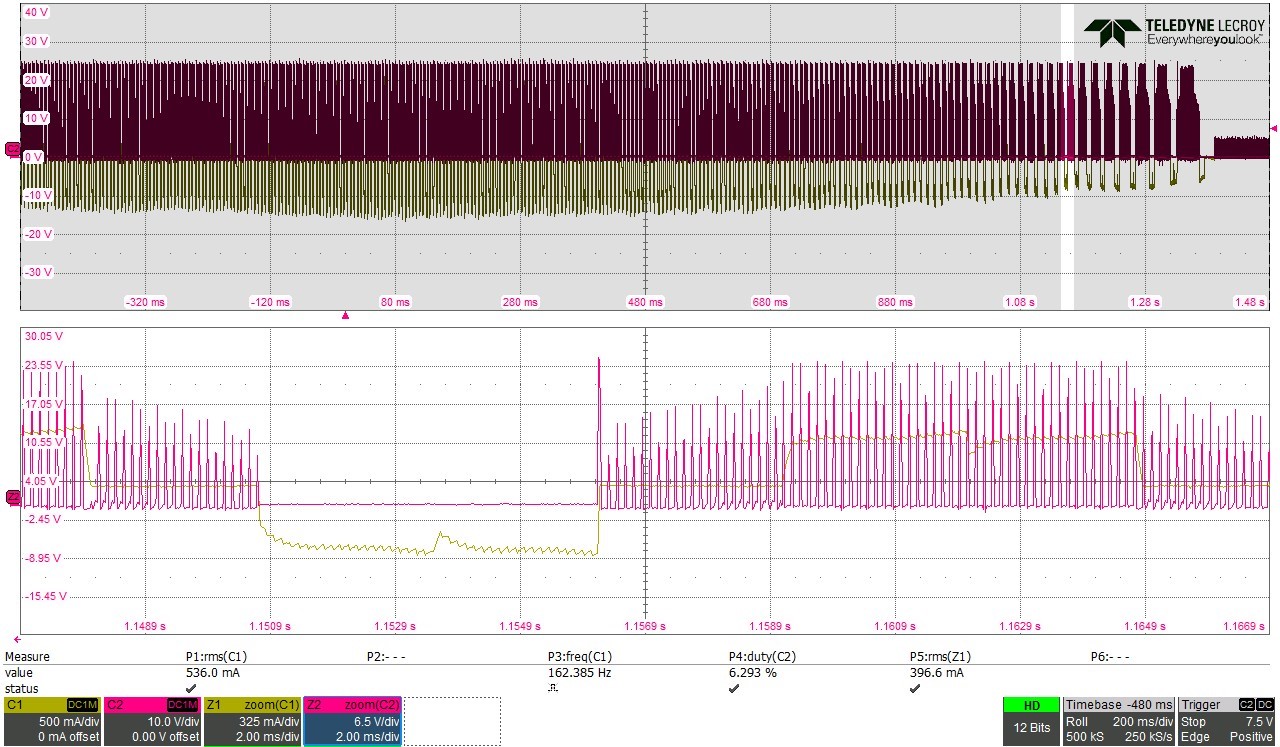

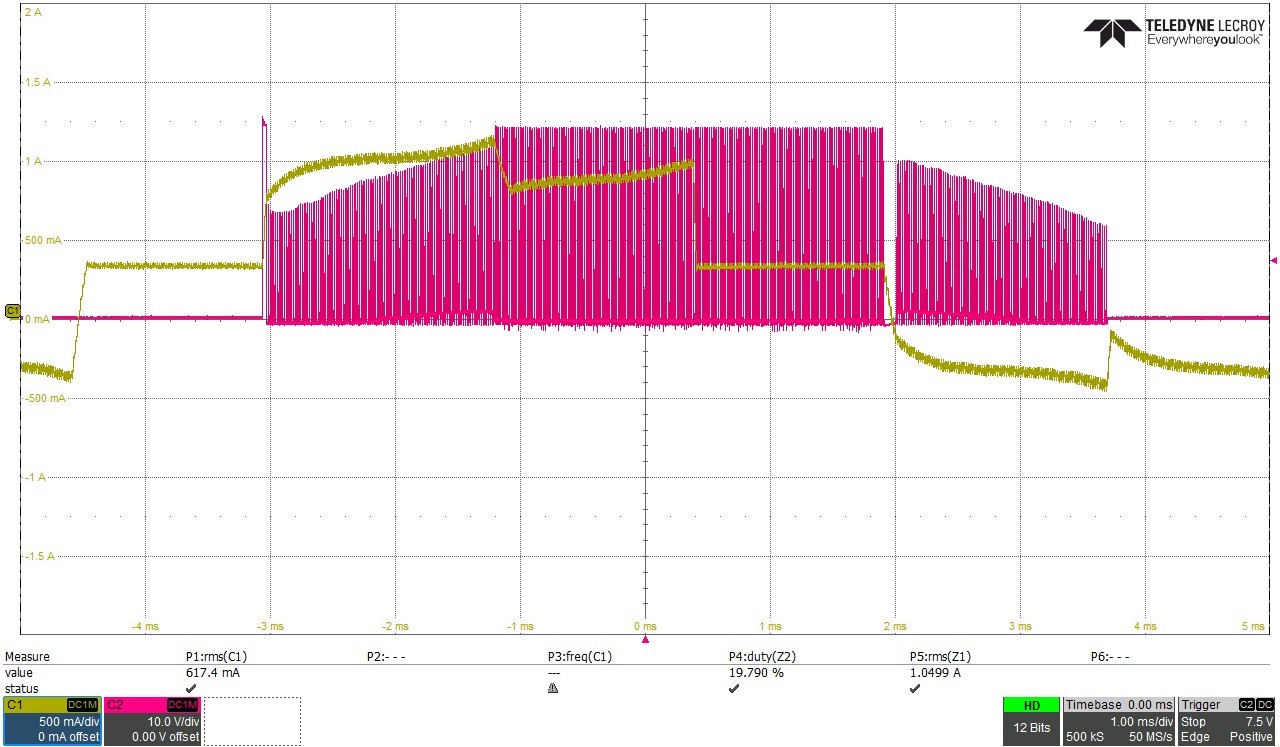

I've noticed that the PWM to the motor is disabled while the motor changes Phase ( trapezoidal phase shift).

when using 20Khz PWM - iI'ts not always occurring,

On the 50Khz PWM cycle I see it all the time.

Also I'm working with a DC brushless motor, and I've tried a few PWM frequencies for the control -18/20/50 Khz.

I was thinking that the faster the Frequency the better.

but it seems like the most smooth operation was with 18KHz, 50 Khz had a "grinding" effect.

I used a pure sinus PWM for both, the driver is limited to 1A. So at the peak of the sinus, I get current limits, but the most grinding is at slower speeds .

Also the motor is 24V winding, we use 32V operation.

Pictures are attached.

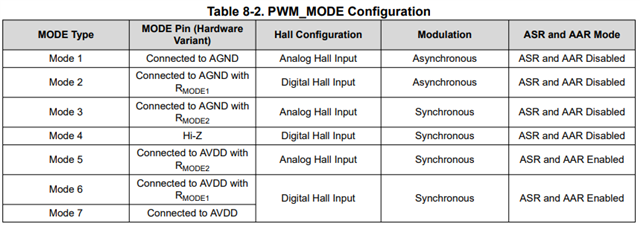

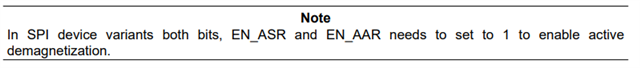

Also For smooth operation - what should I put in the ASR and AAR (Active Demagnetization) ? or they dont have any effect ?

same for the slew rate ?