Hi,

Q1.

Is a Host (MCU or processor) required for the ULC system? In other words, is it possible to write configuration in advance without using I2C?

Q2.

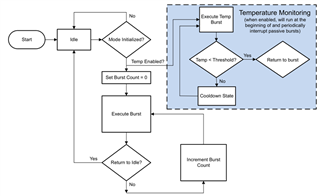

Below are the ULC operation modes described in the datasheet. What does "burst count” in this diagram indicate?

We have been doing GUI-based evaluation and sending commands to vibrate via I2C from a PC.

However, I have not caught up with understanding how it works stand-alone without a PC.

Q3.

Related to Q2, I would like to know the timing of Calibration. Does Calibration need to be done every time ULC starts up? Or is it not particularly necessary after the initial settings have been made in Calibration on a GUI basis? I am wondering if it needs to be performed stand-alone after the ULC is shipped in mass production. As far as I can tell from the documentation, it states that Calibration needs to be done at a temperature of about 25℃. How should this be handled if the APP is to be used in a hostile environment?

Thanks,

Conor