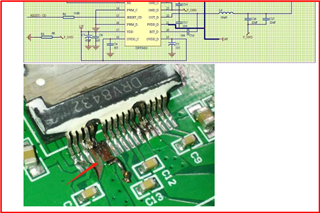

Other Parts Discussed in Thread: DRV8262, DRV8412

Hello TI FAE,

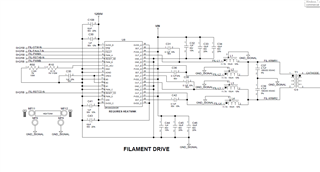

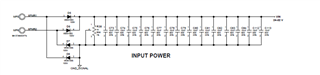

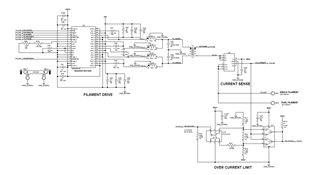

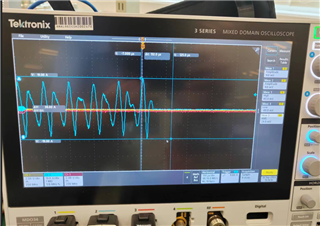

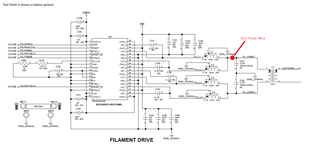

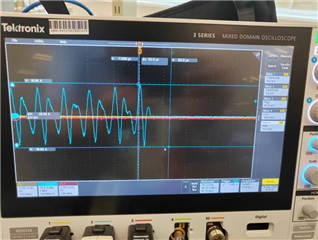

Here we have met DRV8432 short circuit issue on our tank filament board. Detailed schematic is below, also we have a PPT for initial analysis

Tank_Filament_Board_Failure_Analysis_20230909.pptx