Other Parts Discussed in Thread: , DRV8962

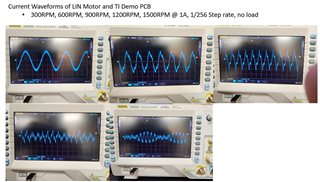

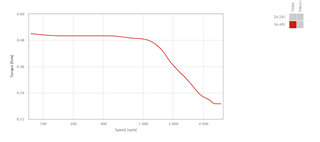

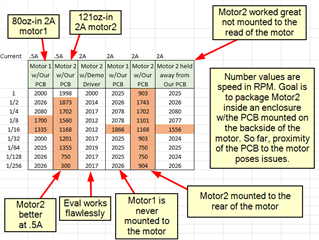

I have a circuit (uP, driver, supply) staged on the backside of a NEMA 17 stepper (120oz-in, 2A, 3.9mH, 48VDC). I notice when we separate the pcb away from the motor by extending the phase wiring, we're able to step/microstep up to 1500rpm. When we mount the pcb on the backside of the motor (to utilize a rear magnet for encoder) we see that we start losing step and stall rather quickly (its better at full step but gets worse as we start cutting the step rate). It appears we're running into some EMI/noise. What are some go-to items that you would check that are in place? Or better yet, who has ran into this scenario and what was your solution? Thanks much in advance, this forum is great.

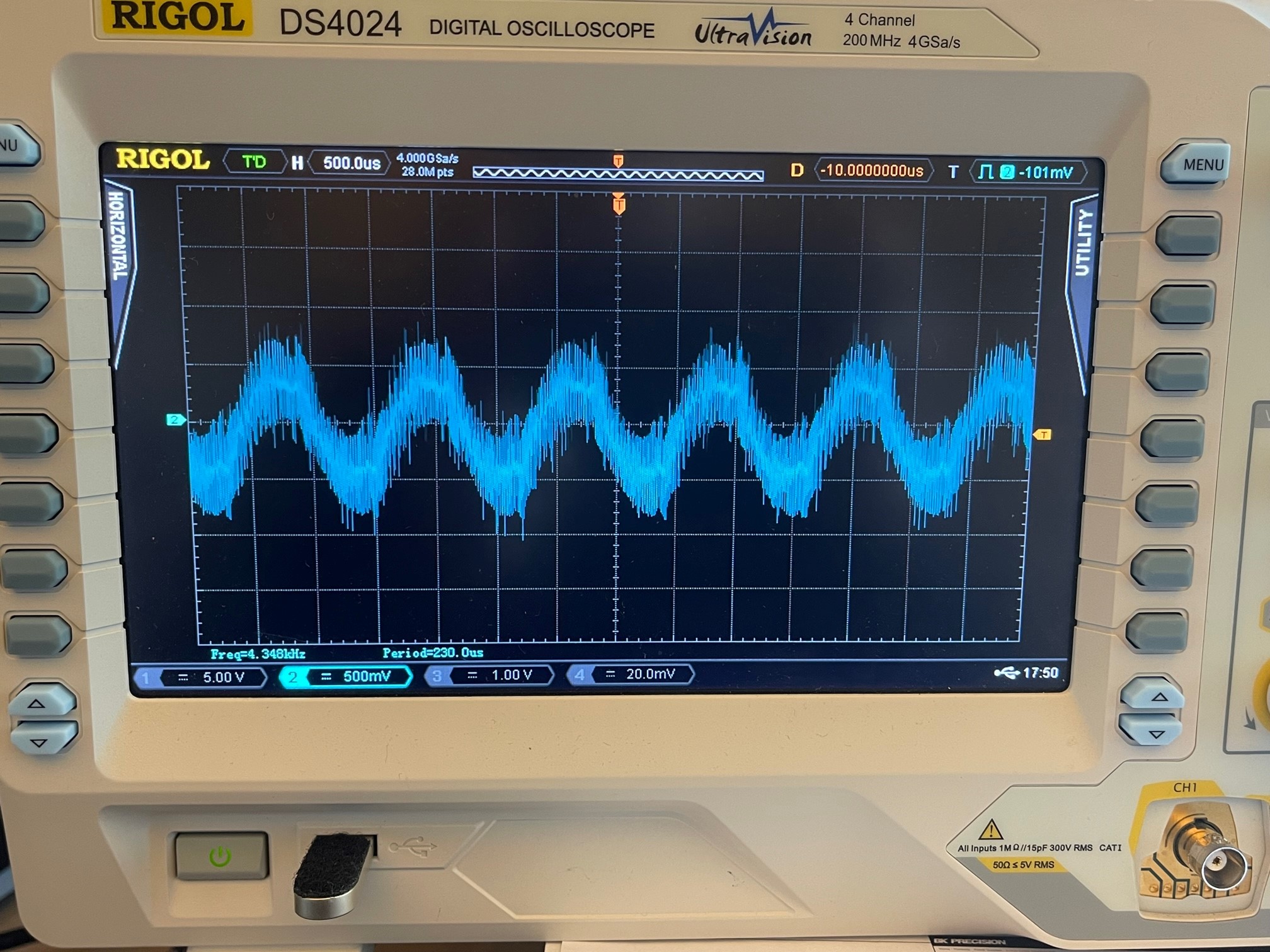

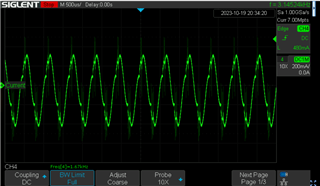

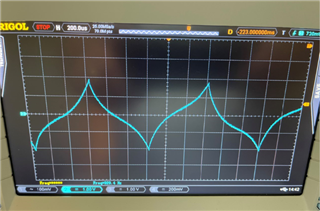

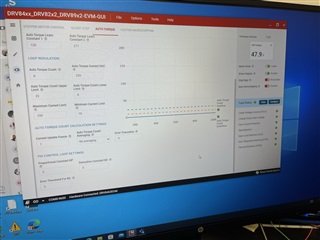

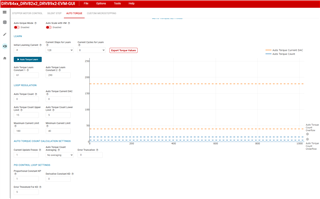

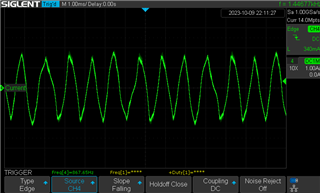

prior to stall, reaching current level

prior to stall, reaching current level starting to get close, is current being reached by driver?

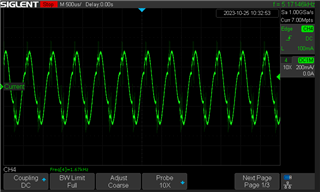

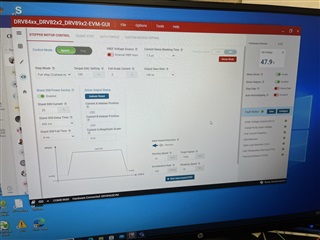

starting to get close, is current being reached by driver? starting to get wonky when decay mode starts to shift (?)

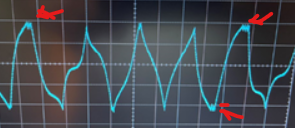

starting to get wonky when decay mode starts to shift (?) aaand we're stalled.

aaand we're stalled.

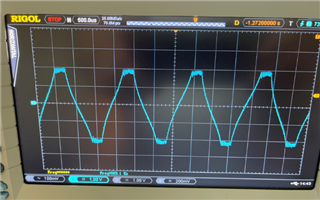

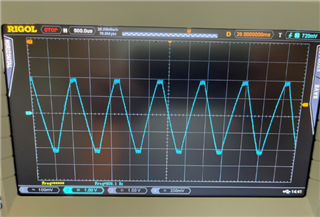

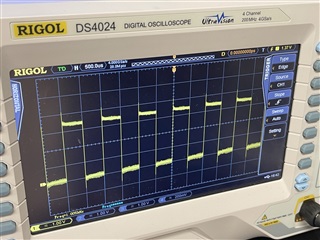

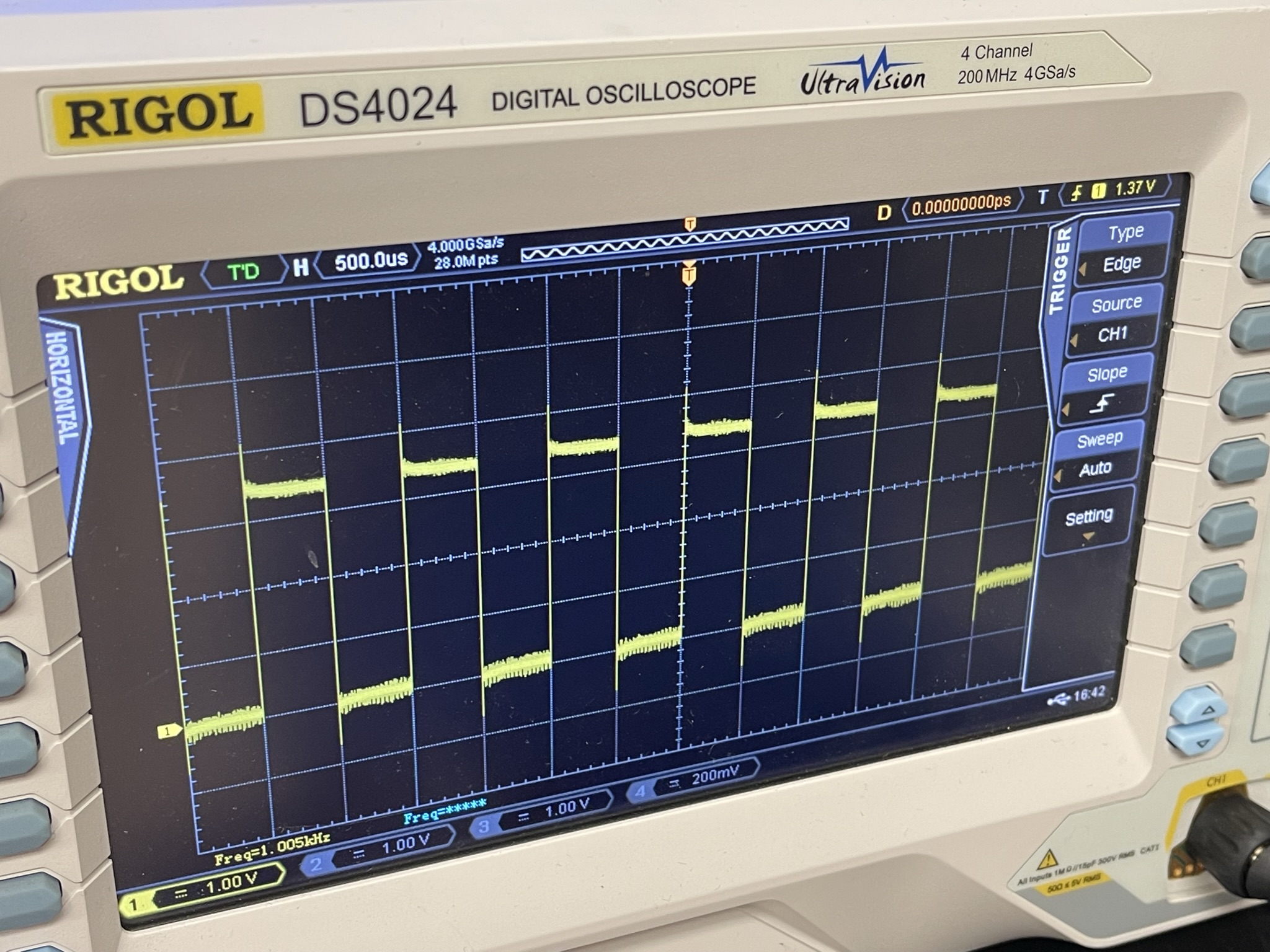

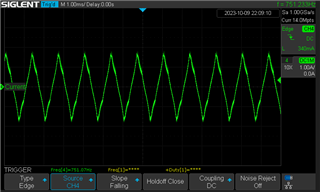

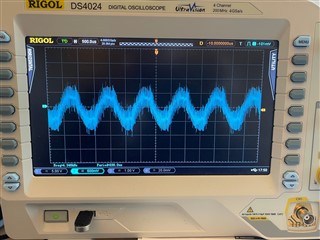

This is the step pin when Motor2 is inside the enclosure.

This is the step pin when Motor2 is inside the enclosure.

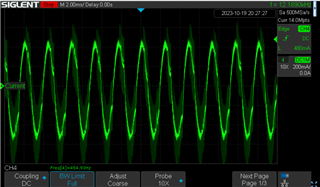

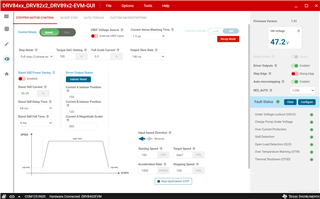

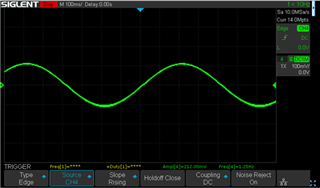

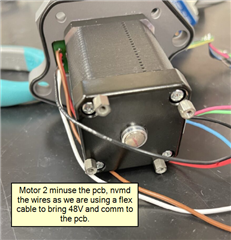

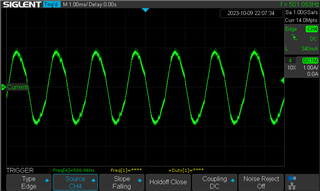

our setup @256 step, .5A, 1000rpm

our setup @256 step, .5A, 1000rpm