Other Parts Discussed in Thread: DRV8424

Hello,

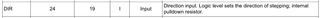

As per the datasheet there is a pull down on the DIR signal?

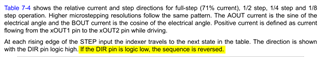

What would be the current flow direction at the output?

Whether it will be clockwise or anticlockwise?

In the datasheet there is no proper information about the direction signal. Please help me to know the current output direction with respect to direction signal.