Other Parts Discussed in Thread: DRV2901, ULC1001

Hello,

I checked the drv2901 datasheet and the evaluation board with ULC1001 and i found that you used a 35V boost converter in the EVM for PVDD.

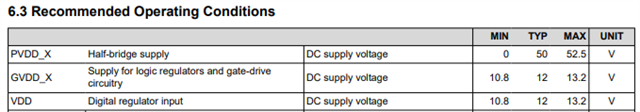

Depending on the datasheet it supports between 12V to 48V and your power supply was 12V

why you didn't use the 12V directly?

what kind of effect to the performance and operation of the system the 12V to 48V input can have? is the piezo cleaning efficiency going to be reduced if 12V voltage is supplied in that case or another issue can happen?

Also how much current will flow between the piezo's terminal?

Thanks