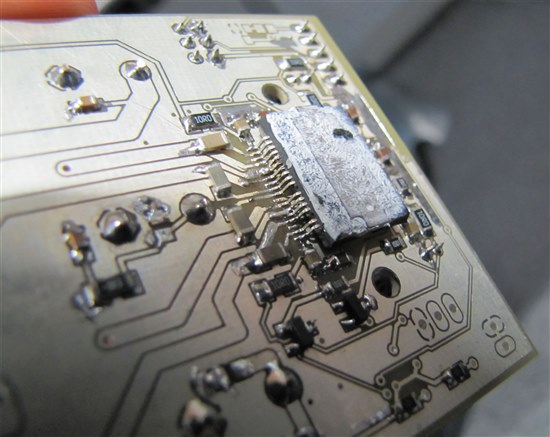

We have just implemented a prototype circuit design using the DRV8402 motor driver in parallel full bridge mode, using the schematic of the evaluation board as a guide. Upon powering up the chip operated as expected, however upon driving a load of 2A for around 5 seconds the PVDD_A/B (34 & 29) pins of the H-bridges appear to have evaporated. The PCB tracks appear to have survived undamaged, so we are quite confused as to how such damage could have occurred to the pins.

I attach a schematic of the board, and a photograph of the damaged chip. If you could advise as to a possible cause and solution for this problem I would be very grateful.