Hi Team,

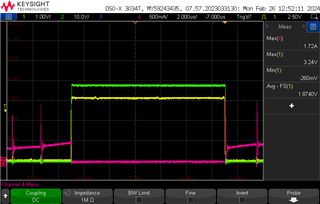

My customer have identified that the motor circuitry is a significant contributor to EMC emissions radiating from their device.

They've been investigating the motor driver circuit and they suspect that the DRV8312 is experiencing parasitic turn-on, causing current shoot-through. This issue could explain the high emissions.

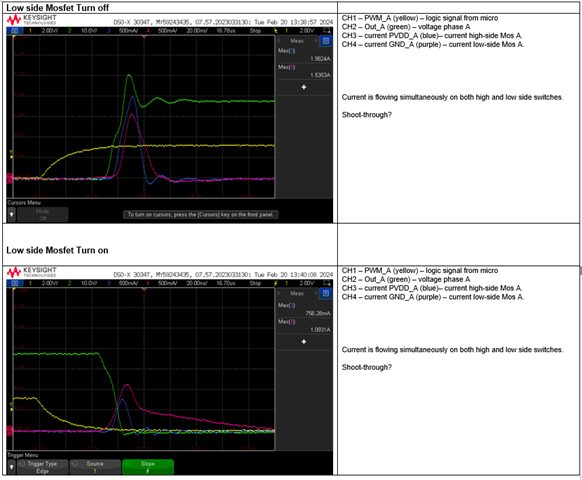

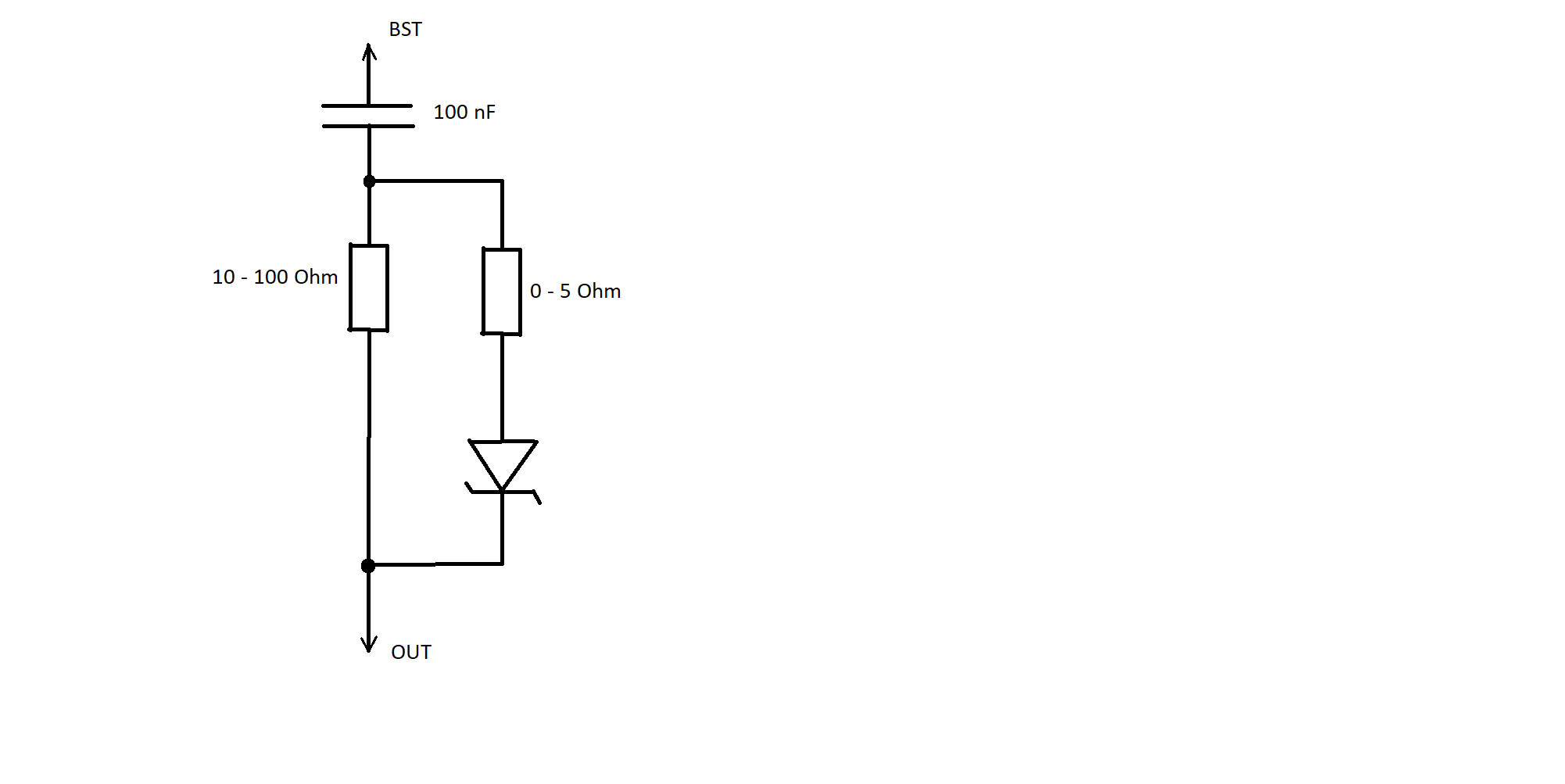

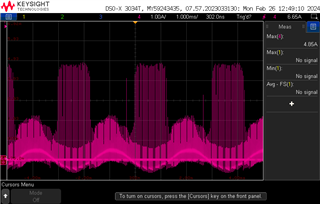

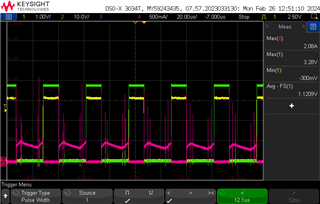

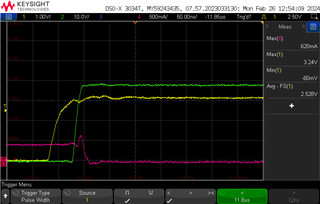

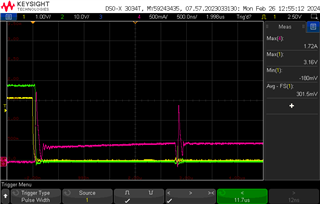

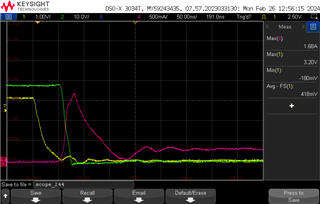

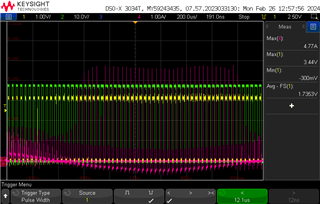

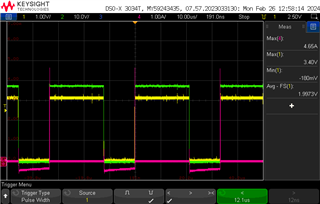

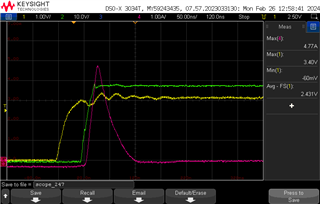

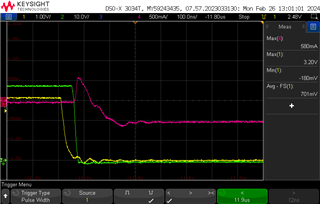

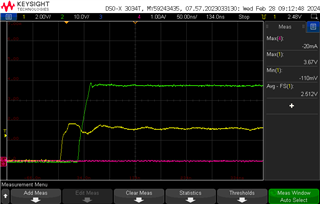

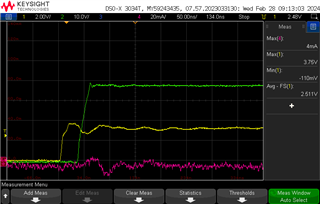

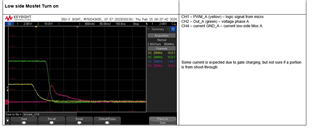

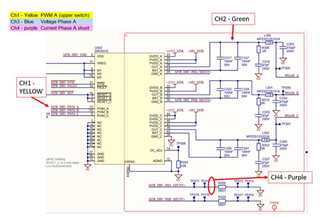

Below are the turn-on and turn-off waveforms for the bottom Mosfet (Phase A).

The motor is not connected, the micro is applying a 50% duty 30kHz PWM to PWM input phase A only.

Since there is no load, the diodes are not conducting, they don’t expect any reverse recovery.

For the turn-off (bottom Mosfet), they see a 1 Amp peak current. However, for this condition, they would not expect any current to flow through (unless they're missing something).

Could this be a parasitic turn-on, lifting the gate voltage caused by high dV/dt (possibly induced by our layout)?

For the turn-on, they see a smaller peak current, which I understand to be the gate charge (and plus some shoot-through as well?)

Unfortunately, they don’t have access to the gate voltage to see if it is going above the Vgs threshold.

Can you please help us understand this turn-off waveform?

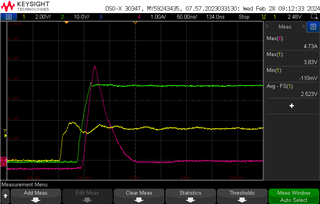

they did the same measurement for phase B, but less intrusive, using a voltage probe across the shunt resistor and they see the same peak current.

(instead of cutting the track and adding a wire-loop for the current probe which can add inductance to the circuit)

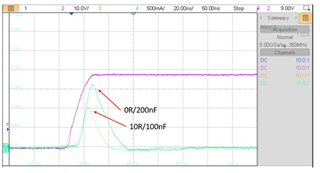

There are snubber capacitors connected to phase A, B, C to GND, these seem to help emission.

For the waveforms above, they removed the capacitors to eliminate the possibility of shoot-through caused by them.

Please kindly advise, thank you and appreciate your time.

Best Regards,

Ernest