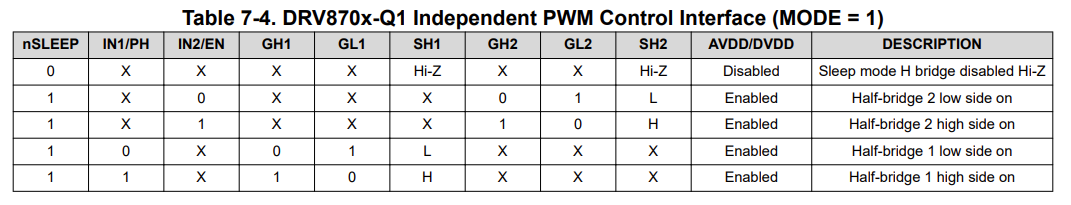

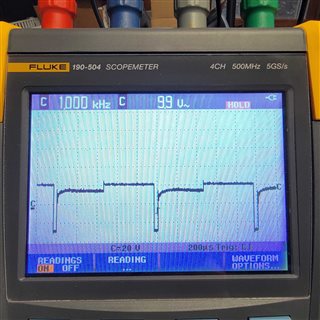

Other Parts Discussed in Thread: DRV8245-Q1, DRV8462, DRV8234, DRV8962, DRV8214, DRV8262

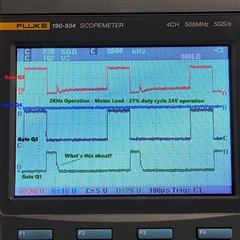

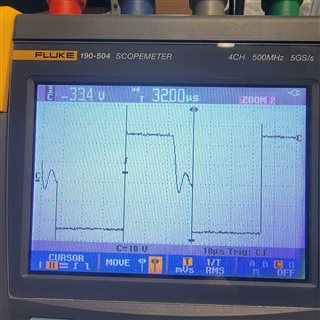

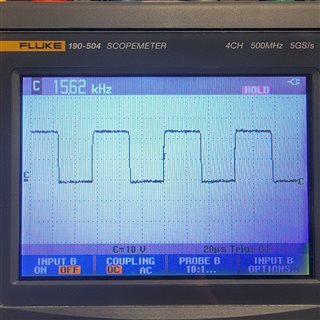

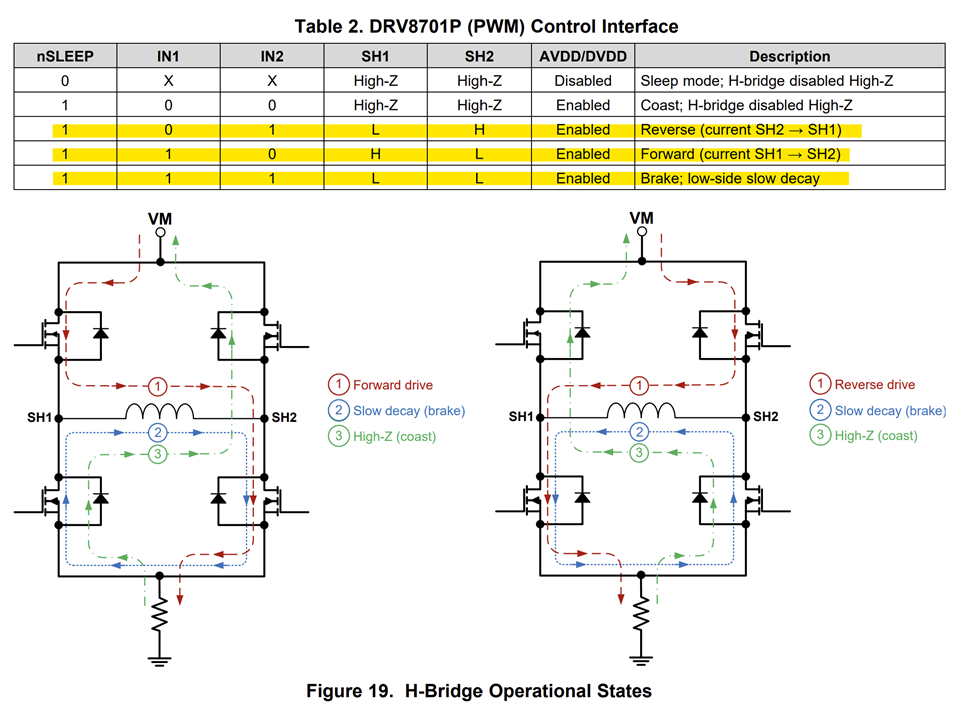

I am trying to replace ST VNH5019 with DRV8701 and External FETs. Schematic below. I suspect given these FETs that I should be running iDrive at the 25/50mA. The VNH5019 had very good response with our motor when running at 15Khz. We had good low-end control down to 35% duty cycle. Running the DRV8701 in this configuration (15Khz), the motor would barely move if at all at 50% duty cycle. If I run the DRV8701 at 1KHz then I get really good control of the DRV8701 down to 20% duty cycle, but then there is the 1Khz audible noise. At 2KHz and 5KHz duty cycles, control of the motor at low duty cycle falls off.

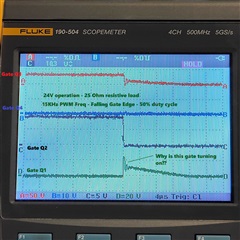

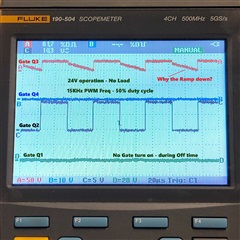

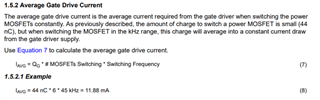

Given this circuit and the same motor as the VNH5019, why does PWM frequency affect the motor control at lower duty cycle from 20 to 75%? I also have Oscope screen shots at some of the various frequencies.

It has been suggested by some to change the zero ohm resistors R1, R2, R3, R5 to some other value. But isn't that the point of the iDrive? Slew rate control.

Further, at the very beginning of the OFF period of the two active FETS (one high side and one low side), the other high side FET turns on for some amount of time. This is more distinct at lower PWM frequencies and looks more like a right triangle