Hi Expert,

I encountered some difficulties in the debugging process.

Now I can do SPI communication , but I can't get PWM.

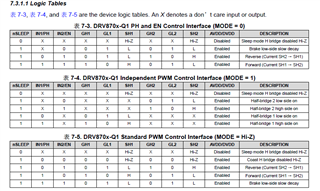

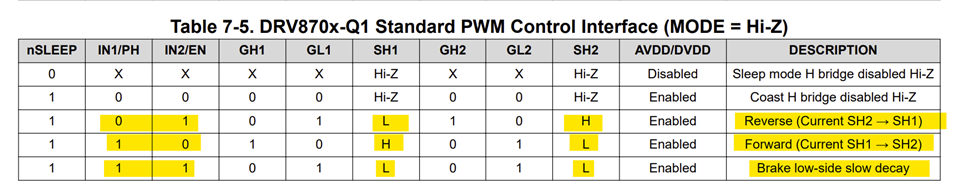

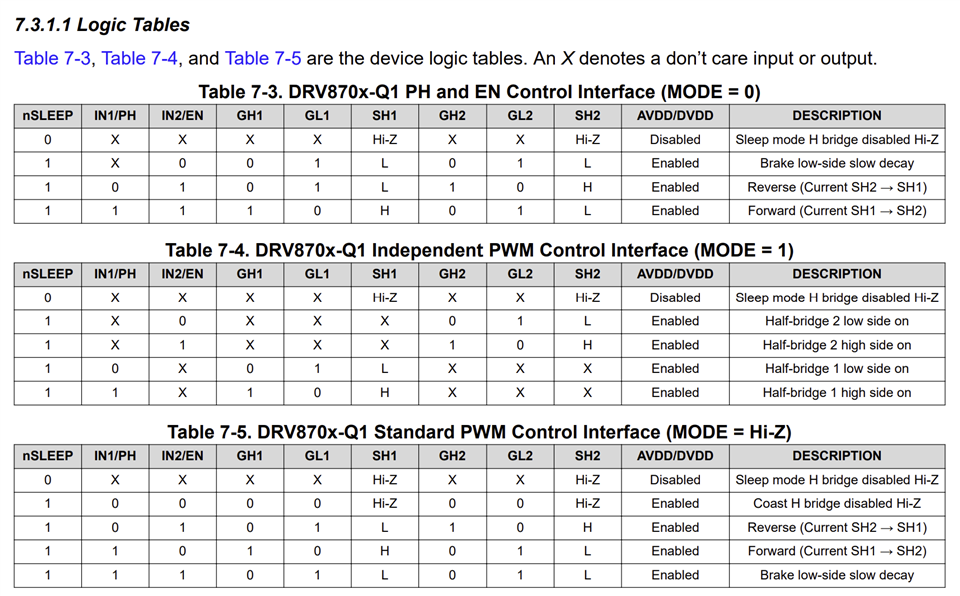

According to my understanding,as long as I set "nSLEEP" = 1,"mode" = HiZ , "IN1" = 1 "IN2" = 0, I will get PWM.(Please remind me if I'm wrong)

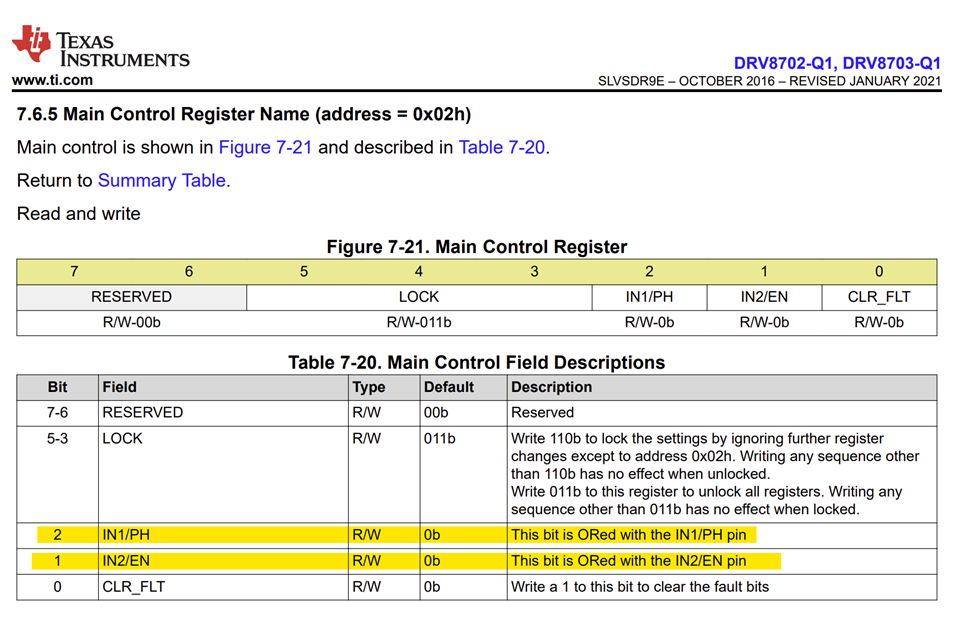

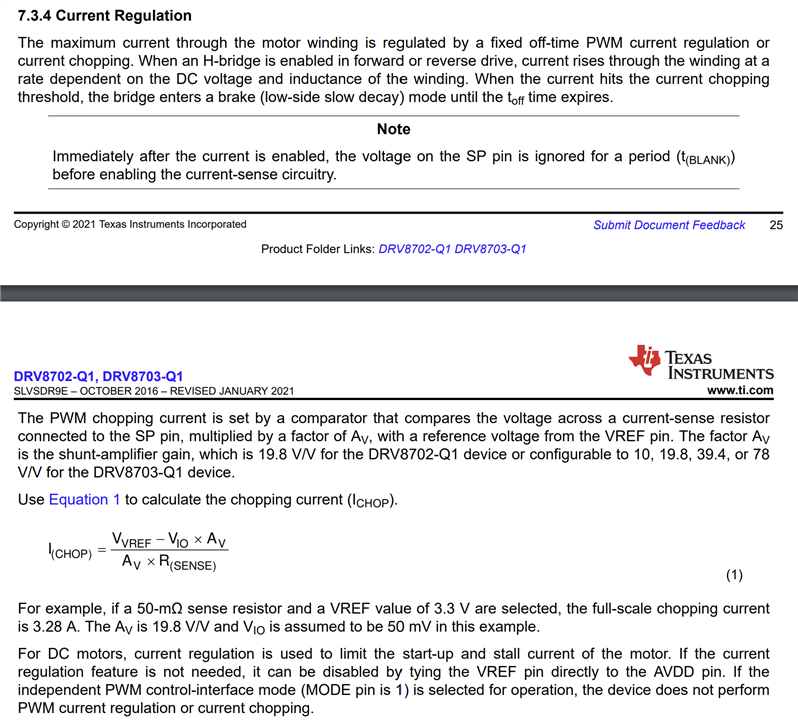

But I set "nSLEEP" = 1,"mode" = HiZ , "IN1" = 1 "IN2" = 0 , VDS and GDF Status Register = 0x04.And no matter how I configure it , VDS always overcurrent.I wonder if I missed something

BR,

Huan Yin