Other Parts Discussed in Thread: DRV8234

Hello!

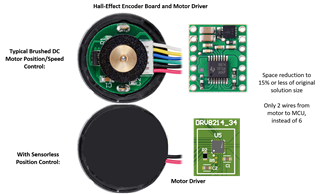

I am working on new design and want to eliminate external sensors and have a couple questions about the benefits.

- Would I pay more for DRV8214 or DRV8234 with integrated speed/voltage control and position control?

- How does this save me money or board space? I don’t want to spend money if I’m not gaining anything.