We are considering using TI's Motor Drive IC (DRV8256ERGER).

We would like to ask you to review the circuit configuration and overall suitability for use.

If there are any other considerations other than the three below, please mention them.

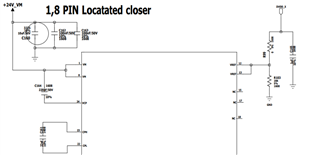

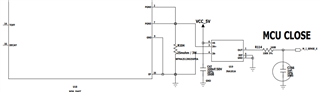

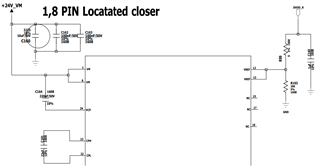

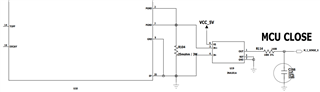

1. Circuit review

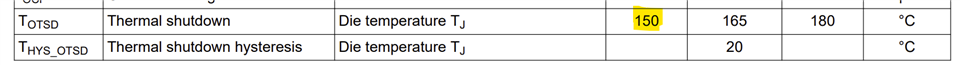

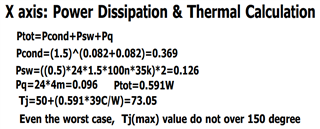

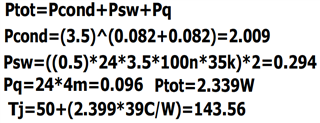

2. Suitable of Tj calculation (inner MOSFET)

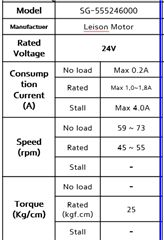

3. Review of Motor Specification (Suitable to use this motor drive IC)