Questions:

- How to achieve a low noise performance of stepper?

- What impacts noise of a running stepper?

- Which drv8711 driver configurations impact noise?

- How to achieve a minimal vibration performance of a stepper?

- What causes vibration of a running stepper?

- Which drv8711 driver configurations impact vibration?

- Are the below current waveforms expected?

- Do higher frequencies cause triangular/square current waveforms?

- Can we set configurations such that the current waveforms are sinusoidal for all ranges of speed (1Hz to 250kHz)?

- For accelerating and decelerating the stepper, do we need a non-zero starting speed and stopping speed?

- Why?

- Why powering on motor (setting enable on CRTL Register of DRV8711) makes the motor jump/jerk?

My setup configuration is as follow:

- Stepper Motor: Bipolar Stepper Motor Frame Size 23 200.0 Step 2.8 A 24VDC

- Power Supply: 48V

- DRV8711EVM board

- Using most of the recommended settings from DRV8711 Quick Spin and Tuning Guide:

- Register Hex Value Settings

- 0x01 Torque 0x0180 Torque = 80

- 0x02 Off 0x0032 Internal indexer, 25 µs off time

- 0x03 Blank 0x0100 Adaptive blanking, 1-µs current blanking

- 0x04 Decay 0x0510 Use auto mixed decay, mixed decay time has no effect.

- 0x05 Stall 0x0A02 BEMF/8, Stall after 2, approximately 20 mV (without experimentation yet)

- 0x06 Drive 0x0000 Minimal drive, minimum OCP deglitch and threshold

- 0x00 Control 0xxxxx 850 ns dead time, gain of 10, internal stall detect, 1/128 step, enable motor

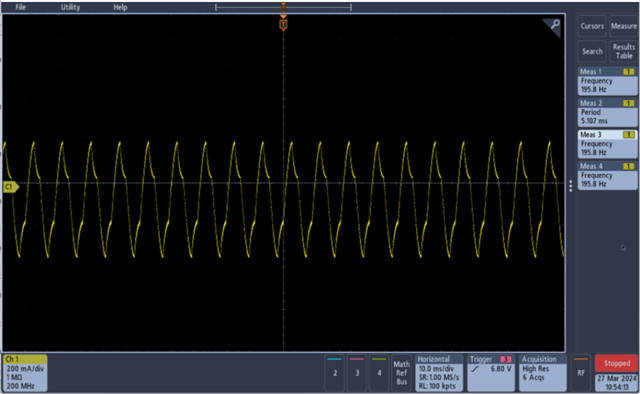

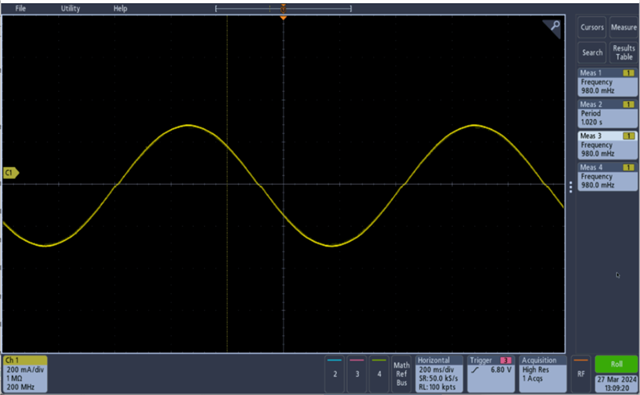

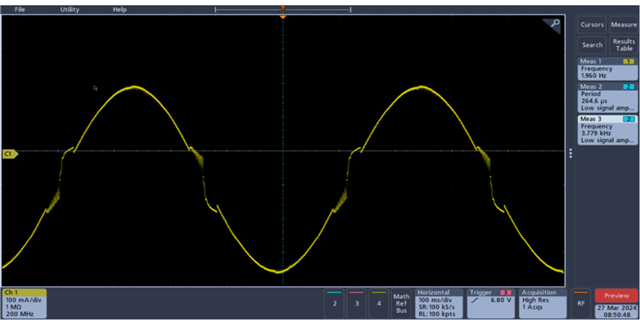

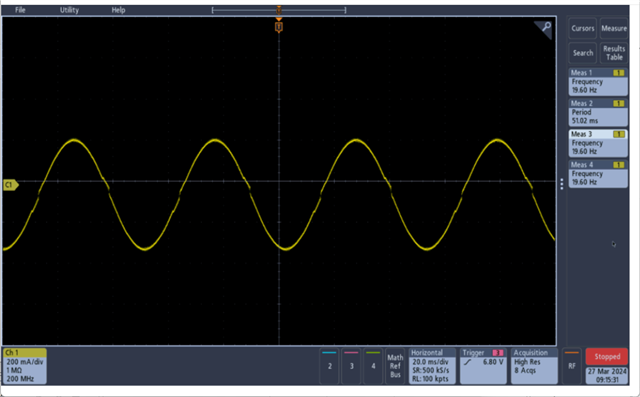

One winding current waveform are measured below at varying indexing speeds:

Period = 1000 us

Period = 100 us

Period = 10us