Other Parts Discussed in Thread: DRV8711,

HI,

I am doing some motor control development and are using the DRV8711 but are running into some challenges and are looking for some help with our development process.

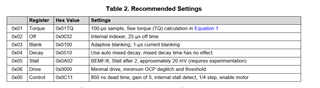

Out setup is a DRV8711EVM but we are using an external MCU to control it. The pins we have connected to our DRV8711EVM are CLK, MISO, MOSI, CS, STP, SLEEP and DIR. Both boards share a common GND The remaining pins are connected in the default state. we are using a 2.8A 1.1 Ohm NEMA 23 style stepper motor (5718L-01P). we are operating in indexer mode and our register configuration is as listed below, the only difference is that we are setting our gain to 10 and Torque to 86

We were having some unexpected behaviors so we decided to change out testing approach by reducing our step resolution to a full step and try and resolve our problems. We have a few issues but for the sake of the thread we will mainly be discussing one, Vibrations while moving.

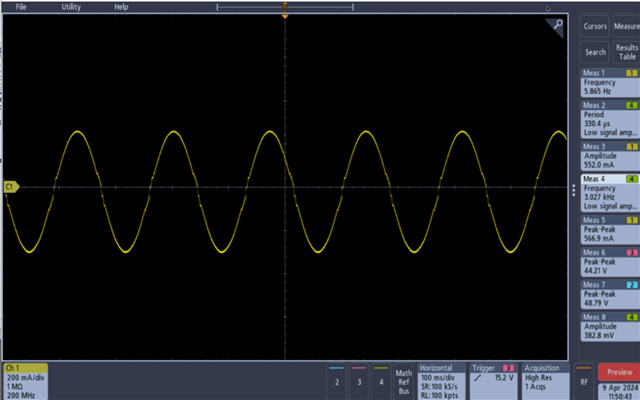

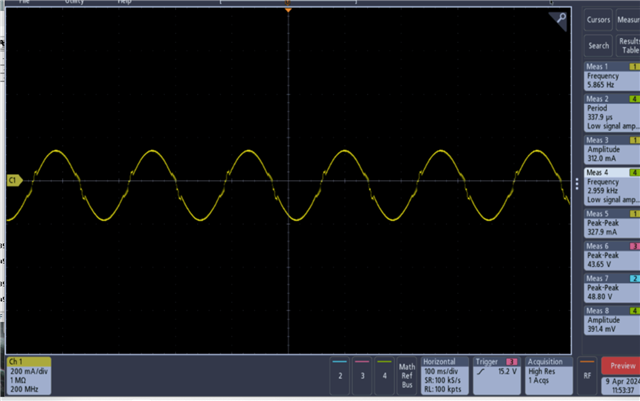

In the first video labeled Video 1 we were attempting to move the motor a 1/4 turn (90 deg) per second. Our frequency to the indexer was 50Hz. We then changed the speed during to 1/2 turn per sec (100Hz) and then finally 1 turn per Sec (200Hz). As you can see in the video attached the motor makes audible noise and vibrates while it is being run.

Q1: Can you provide some insight into this phenomenon and what we can do to eliminate this?

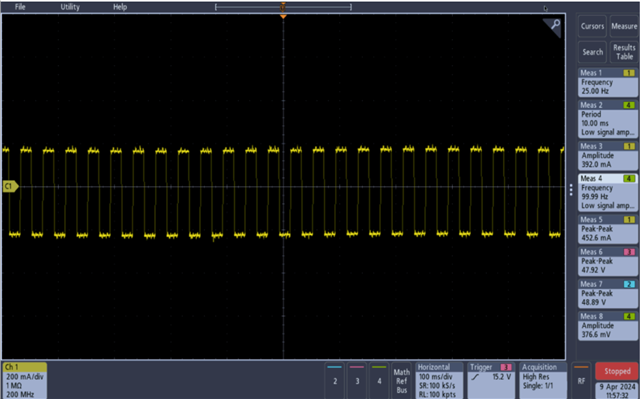

As for the 2nd video we kept the settings the same and changed the step resolution to 256 at 50Khz. As you can see the motor vibrated a lot and kept jumping during motion

Q2. Can you provide some insight into this phenomenon and what we can do to eliminate this?

Thank you in advance for advice on this issue, we are happy to provide any more information as needed. We have custom boards designed based on the DRV8711 but we will like to use the EValuation board to eliminate the chances of an error in our PCB Design

Best

afam