Hello.

I would like to ask about DRV8245-Q1 device.

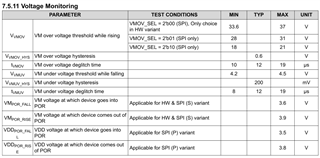

1. In SPI(P), (VM undervoltage translators) is a question about how long and how much voltage it is.

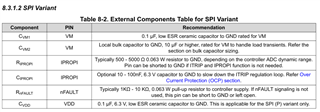

2. Apart from the SPI connection, which pins should be essential to the MCU? Is there any function that SPI can replace?

- EN/IN1, PH/IN2, nSLEEP, nFAULT

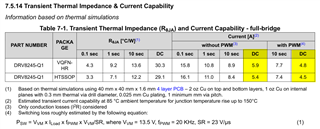

3. I would like to ask if I can use more than 5.5A continuously (1oz 6Layer)

-

Ask a related question

What is a related question?A related question is a question created from another question. When the related question is created, it will be automatically linked to the original question.