Dear team,

Tests found that the DRV8889-Q1 cannot diagnose open circuit faults below -30 degrees Celsius, but it can still drive the motor. (Open circuit can be diagnosed at room temperature.)

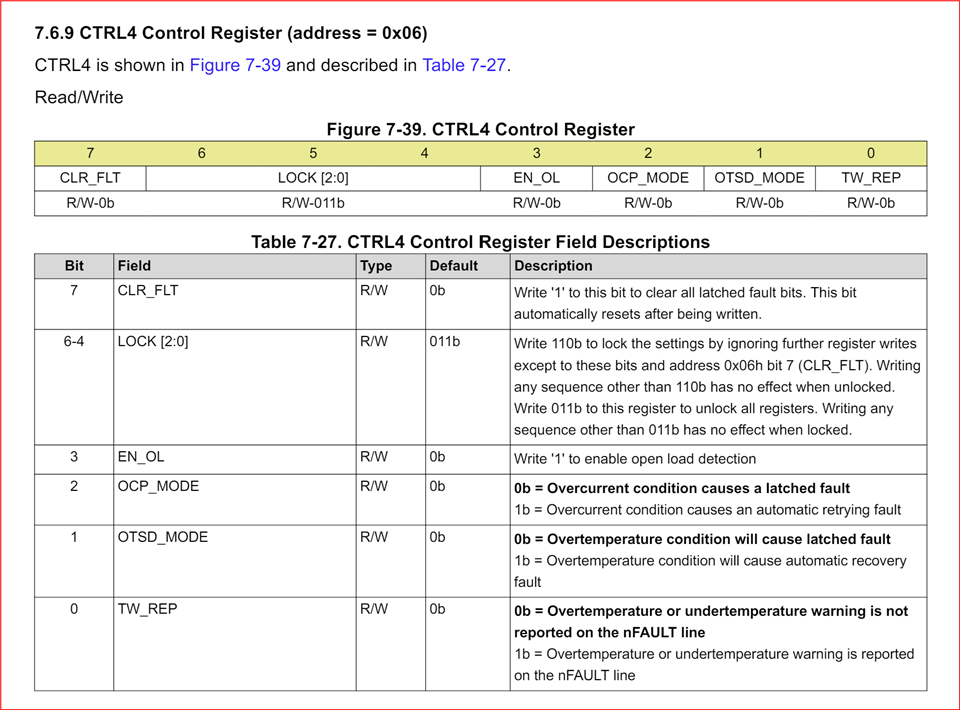

The low temperature of -30 degrees is lower than the under-temperature warning threshold TUTW[-25 -10 5]. How to explain this problem?