Other Parts Discussed in Thread: MOTORSTUDIO

Tool/software:

Hi TI,

In the datasheet, Motor lock, Hardware lock, and Software lock are mentioned, which makes me a little confused.

1.Are these three locks always enabled during usage of MCF8316C-Q1?

2.What are the differences among these three locks? Could you kindly give some instances?

3.There are 2 design requirements in our product:

(1)one is stall detection

I think it could be achieved via LOCK_ILIMIT. We configured LOCK_ILIMIT to some value which is bigger than the rated peak current, held the motor rotor to stationary state by manual, and we could see LOCK_ILIMIT fault on MotorStudio. I want to confirm if this stall detection method is right or not;

(2)the other is speed abnormal detection

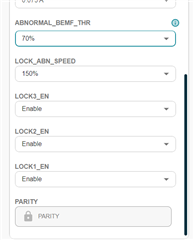

For example, the motor is spinning at the target speed 600RPM, someone tried to press the motor rotor and slow down the speed to around 500RPM, could MCF8316C-Q1 detect this speed abnorma default by itself?

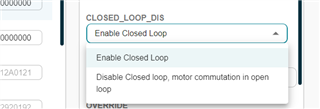

I tested Abnormal BEMF (ABN_BEMF) mentioned in section 7.3.22.13.2, but I could NOT get ABN_BEMF fault when I tried to hold the motor rotor and slow down the speed.

Thanks,

Alex