Tool/software:

Hello,

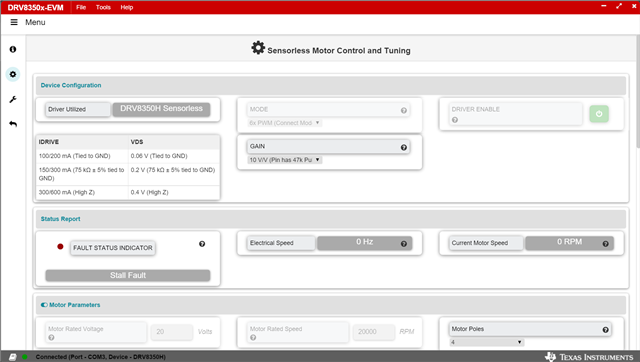

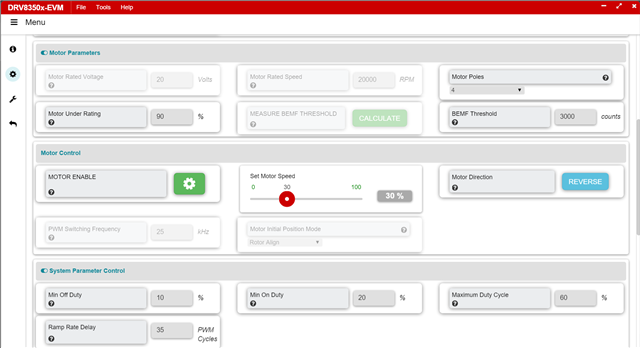

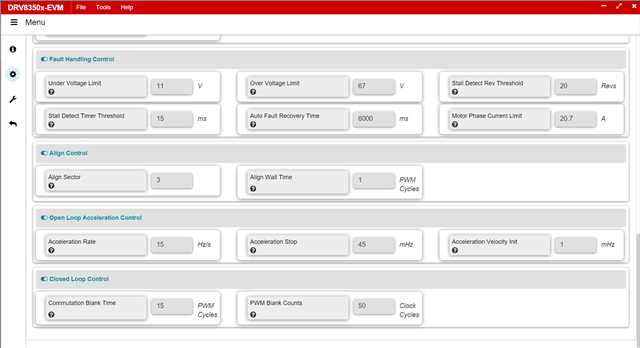

I am encountering issue while tuning the input motor parameters.

I have given motor voltage as 24V and speed as 23000RPM. In open loop acceleration control, for Acceleration Rate I gave as 50Hz, for Acceleration Stop Range = 10,000 MHz and Acceleration Velocity Interval = 10,000 MHz. If I try to enable the motor I am getting error in tuning the open loop parameters. Could you pls provide me clarification to encounter this issue?

Thanks.