Tool/software:

Hi ti team,

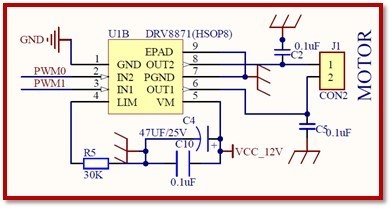

1. We originally expected to rely on the overcurrent stall protection function of the IC to avoid the risk of finger pinch in our product (due to product design issues, it is necessary to achieve anti-pinch by means of the IC or other methods). However, during the testing process, we noticed the following problems, making it difficult to achieve our expectations: When the product gearbox is operating normally (without the addition of the ILIM resistor), the working current is approximately 130 to 140 milliamps, and the maximum current at the instant the gearbox gets stuck is approximately 220 to 300 milliamps. The DC internal resistance of the motor is 7.5 ohms and the power supply is 12 volts.

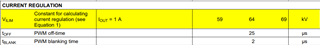

1. When the ILIM resistor is set to 320 kiloohms, the theoretical overcurrent stall current should be 200 milliamps, but at this time, the IC has automatically adjusted the motor current to 120 to 130 milliamps internally. The motor gearbox operates normally, but when simulating a finger pinch that forcibly jams the gearbox and immediately releases the finger, the motor fails to resume operation, and the current remains at approximately 20 to 30 milliamps.

2. When the ILIM resistor is set to 256 kiloohms, the theoretical overcurrent stall current should be 250 milliamps, but at this time, the IC has automatically adjusted the motor current to 120 to 140 milliamps internally. The motor gearbox operates normally, but when simulating a finger pinch that forcibly jams the gearbox and immediately releases the finger, the motor fails to resume operation, and the current remains at approximately 20 to 30 milliamps.

3. When the ILIM resistor is set to 213 kiloohms, the theoretical overcurrent stall current should be 300 milliamps. At this time, the IC has automatically adjusted the motor current to 130 to 160 milliamps internally. The motor gearbox operates normally, but when simulating a finger pinch that forcibly jams the gearbox, the motor fails to start and stop, failing to achieve the purpose of anti-pinch.

Therefore, we expect to have a deeper understanding of the performance of this IC and request support:

1. How much difference should be set between the working current of the motor and the stop current at least to achieve effective stop?

2. Is the failure of the motor to resume startup after start and stop caused by the too small setting of the stop current?

3. What is the minimum stop current that can be set for DRV8871? 4. For the above cases, how should it be set to achieve a more ideal stop protection function? What we expect is to start and stop the motor when the finger just gets caught in the gearbox, instead of waiting until the gearbox is completely stuck (preferably start and stop at a current of 200 to 250 milliamps)