Tool/software:

Dear Sir/Madam,

I would like to control a dual speed wiper motor and am looking at using the DRV8702D-Q1.

There will be one DRV8702D-Q1 for each speed.

I am a little confused how to control DRV8702D-Q1.

I need to do the following:

* Turn the motor on

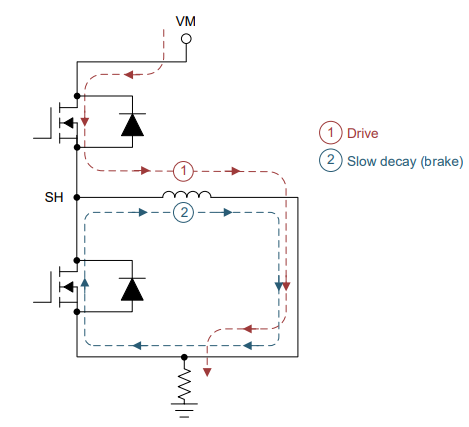

* Turn the motor off quickly (brake).

* Protect DRV8702D-Q1 from induced voltage into low-speed winding.

Simple as possible minimal control pin interface.

Hoping to just use IN1 and IN2 if possible and tie nSLEEP to 1.

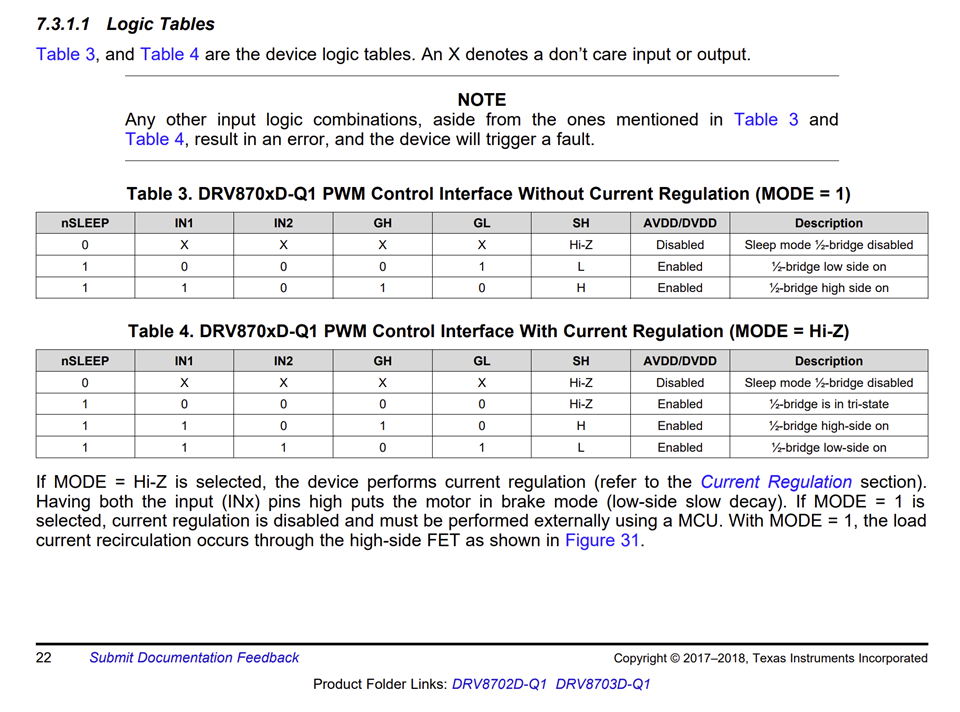

Q1. Do I use MODE =0 or MODE=1

Q2. Can I drive IN1 and IN2 with static DC values or do they need to be PWM controlled?

The following is the sequence I believe.

1. tri-state (motor is off) IN1=0 (high side off), IN2=0 (low side off)

2. turn on motor IN1=1 (high side on), IN2=0 (low side off).

3. wait until instructed to turn off.

4. turn off motor IN1=1 (high side on), IN2=1 (low side on) brake

5. tri-state (motor is off) IN1=0 (high side off), IN2=0 (low side off)

How long do you need to wait at step 4 before going to step 5.

Q3. If voltage is induced into motor winding do I turn off lower and upper FETs?

I understand that I will need to block current flowing into upper FET and also protect SH pin.

The following is the sequence I believe.

1. tri-state (motor is off) IN1=0 (high side off), IN2=0 (low side off)

Regards Joe