Tool/software:

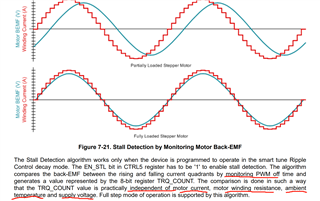

Our company has newly evaluated the customer's HUD project and requested that the bipolar stepper motor drive have the ability to detect locked rotor. After reviewing the drv8889-q1 specification, it can be understood that locked rotor detection can be achieved through phase difference or BEMF induced phase current waveform change time difference, which is not affected by motor current, coil impedance, ambient temperature, and supply voltage. Therefore, I would like to ask for your advice

1. Is it feasible for the high impedance 215 ohm coil internal resistance small bipolar stepper motor we use to be driven with a low current limit of around 40mA and a full step speed of approximately 400pps at low speed?

2. Can we prevent the BEMF reverse electromotive force caused by the mechanical structure's short-term obstruction (detected by a trigger switch in reverse) and the stopping process when the motor rotates to the limit position without judgment? For example, by setting the detection time limit for blockage and rotation to handle it.

3. Please also help evaluate the ability of drv8889-q1 stepper motor driver to detect and compensate for step loss. I understand that it can only monitor the input PWM step signal at most, but compensating or physically compensating for step loss in the final motor mechanical structure should be difficult to achieve from the driver IC end.