Tool/software:

Hi TI,

We are using DRV8889-Q1 to drive the stepping motor, and want to use the stall detection funciton. The motor parameters are as following:

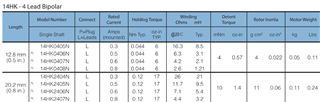

Number of Phase: 2

Step Angle: 0.9 degree

Rated Voltage: 4.8V

Rated Current: 0.3A

Phase resistance: 16ohm

Phase inductance: 8.5mH

Target speed: less than120RPM

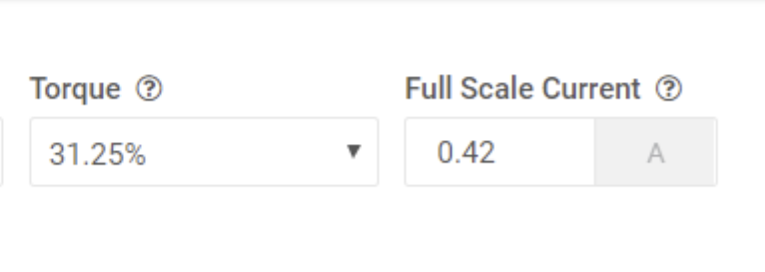

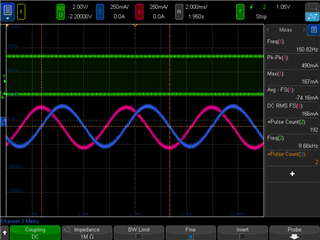

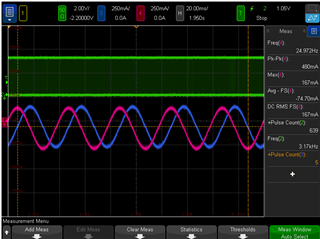

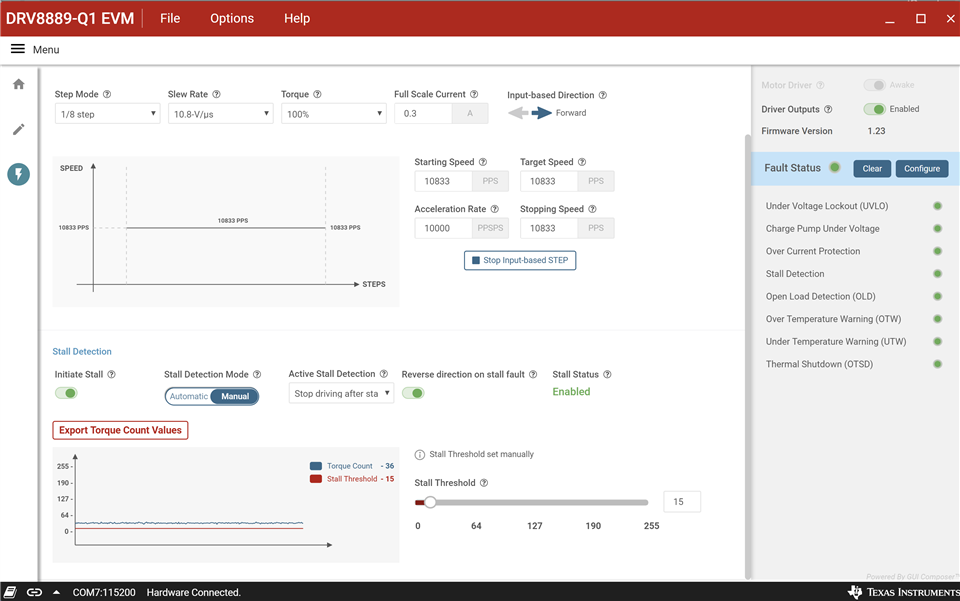

The setting of DRV8889-Q1 UI is as following(Decay mode is set to smart tune Ripple Control decay mode):

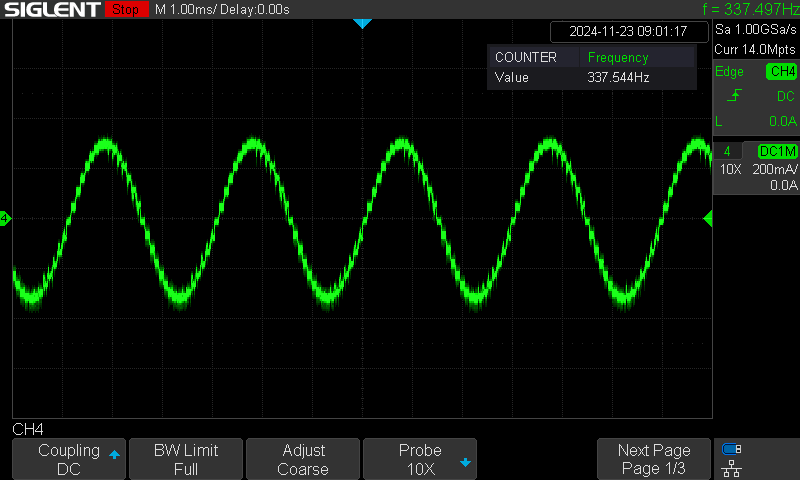

The Torque count was always 0, and the stall fault could not be triggered. What's the reason?

BTW, we want to know if this issue is related to the motor itself? If so, what do you recommend for the motor parameters?

Thanks,

Alex