Tool/software:

Hi everyone,

we are designing a BLDC motor controller using DRV8306 and having issues with PWM frequency.

We are using a 24V 27W motor, R_ISEN = 250mOhm and digital Hall sensors with open-drain outputs.

Schematic and layout of our DRV8306 driver:

DRV8306_Motorcontroller_Schematic.pdf

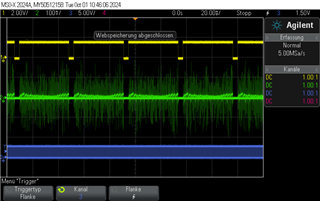

As we set PWM to 30% or higher and then keep it constant and sweep trough frequencies from 10 to 200kHz, the motor speed and its power usage goes constantly up until roughly 100kHz.

At this point, the motor stops, fault LED lights up or the motor drives very poorly while fault LED lights up quite a lot.

As we increase the frequency even more, fault conditions stop, motor speed and power usage increases constantly again to higher speeds than before.

Schematic and layout of DRV8306EVM:

DRV8306_Motorcontroller_Layout.pdf

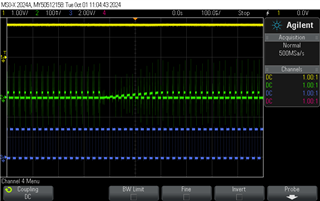

After comparing our design with the DRV8306EVM, we lowered the value of R_ISEN with two parallel 250mOhm resistors to 125mOhm and the PWM frequency dependency was solved.

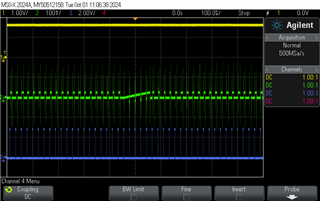

Then we lowered R_ISEN even more with three parallel 250mOhm resistors to 83mOhm and the motor drove very poorly and inconsistent, even more than initially, regardless of PWM and PWM frequency, so switched back to 125mOhms.

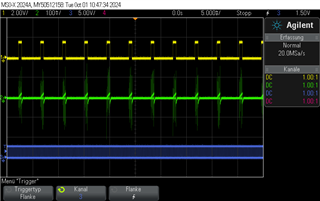

Then we added a 4,7µF capacitor parallel to the voltage divider between the Hall negative rail and ground and increased the capacitor attached between DVDD and ground from 100nF to 1µF and the fault condition at around 100kHz PWM frequency was solved.

Now the motor works nearly as good as it does with the DRV8306EVM.

Can you explain this kind of behaviour so that we can design a properly working bldc driver?

Thanks,

Tobias