Tool/software:

Hi:

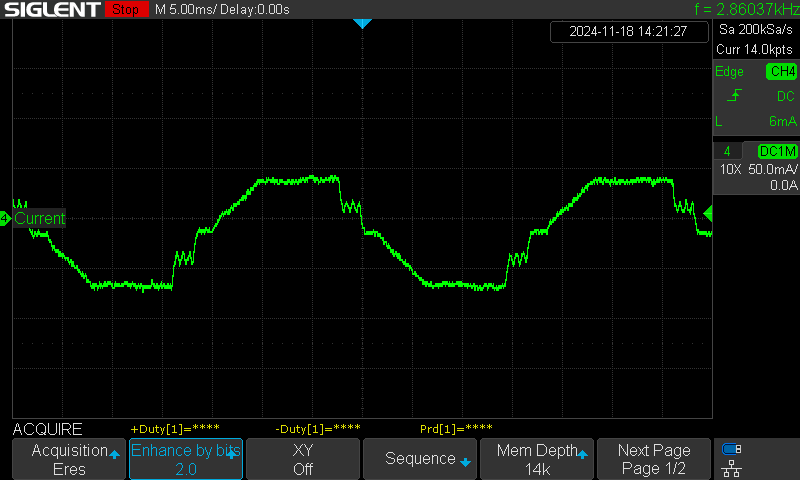

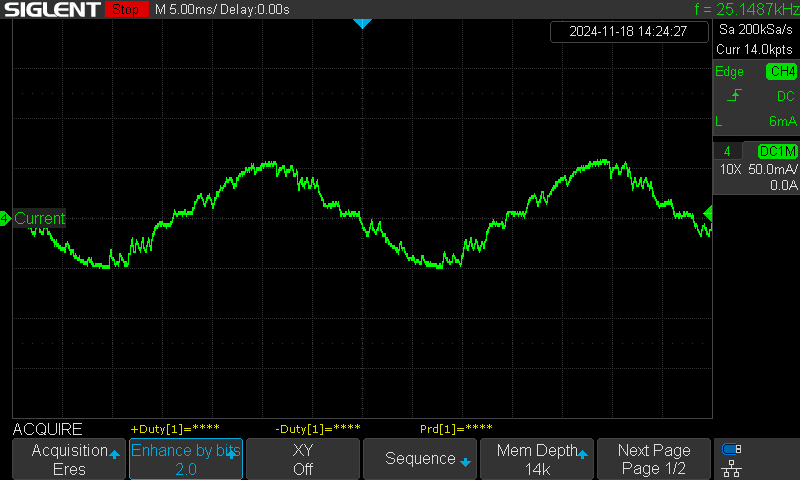

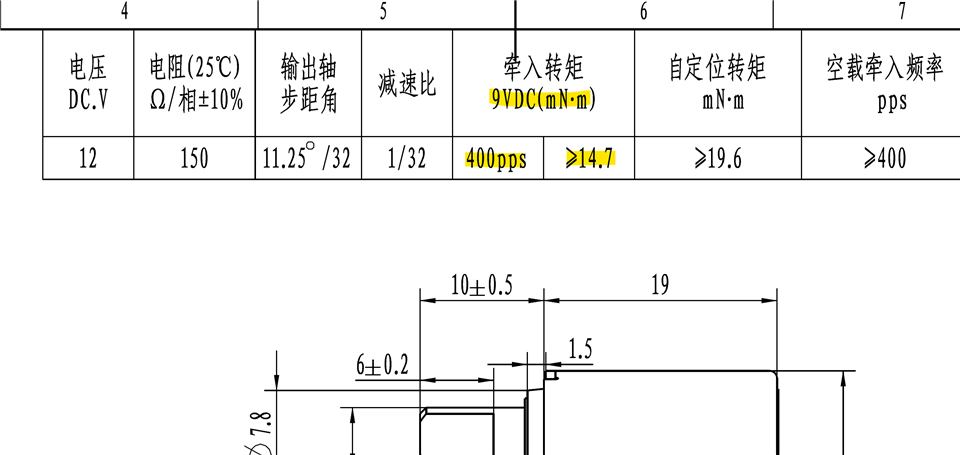

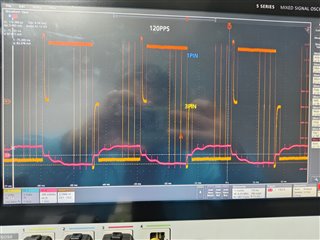

We use 8889A to drive the motor, configured for 1/4 micro step, Smart tune Ripple Control mode, providing 480 pulses per second on the STEP pin, and the motor noise is very loud. We also tried other PPS and micro step parameters, but the motor noise did not significantly decrease. The motor supplier told us that the motor drive current cannot be reduced, otherwise the motor cannot be driven. How can we reduce motor noise and make the motor drive waveform approach a sine wave. Q24BYJ48-3361w.pdf

Q24BYJ48-3361w.pdf