Other Parts Discussed in Thread: DRV8718-Q1, DRV8714-Q1

Tool/software:

Hi,

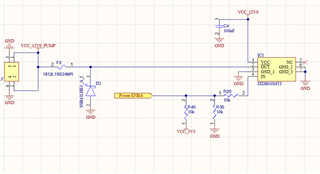

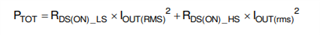

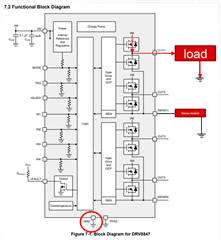

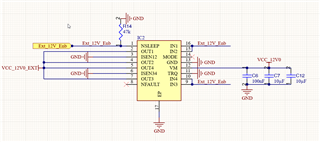

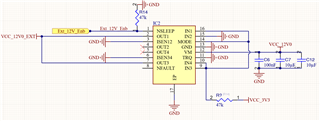

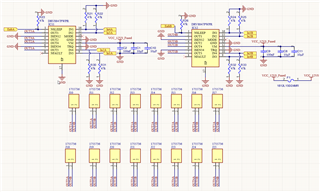

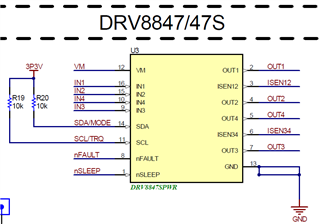

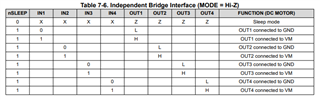

This is my design as shown below. The aim is to have 16 independent latching solenoid drivers, but for some reason, it was not able to output a high voltage of 12V. The maximum voltage being output was 0.7V.

After some investigation, I noticed that ISEN12 and ISEN34 were left floating. As I did not want to limit the current, these were left floating. However, I believe the correct approach would be to connect these to GND. This will be addressed in the next version of the PCB, where they will be connected to GND.

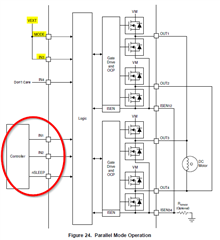

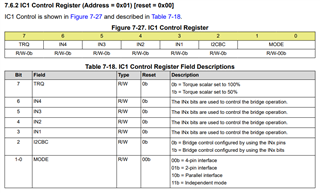

The question I have is regarding the TRQ pin. It seems this also affects the output current. How should this pin be set?

Thank you.