Tool/software:

Hello,

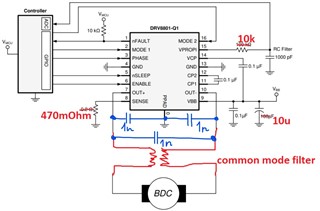

We are using DRV8801QRTYRQ1 in our current design - an actuator with a 12V BDC motor. The housing is made of plastic.

Power supply - 24V, PWM duty cycle - 50%. The length of the tracks from the driver to the MCU is about 40-50 mm. The sense resistor 470 mOhm, is placed close to the driver. In normal conditions, nFAULT is high even if the motor's shaft is blocked.

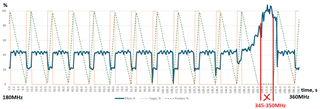

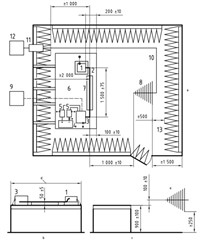

We conducted RF immunity test according to ISO 11452-2 (Absorber-lined shielded enclosure): 100MHz...2GHz, 100V/m.

During the test, we faced motor stops at some frequencies, about ~340-350MHz and ~380MHz (it's difficult to define exactly). nFAULT signal goes low and the driver is shut down (it looks like overcurrent protection triggered). Temperature and input voltage were controlled during the test and did not go beyond normal values. What could be the problem and how can the design be improved in terms of RF immunity?

Best regards,

Yauhen