Other Parts Discussed in Thread: MCF8316D

Tool/software:

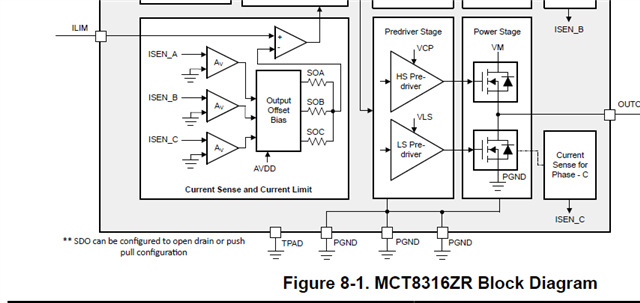

MCT8316Z SPI version does have internal phase current Isense feedback however these signals are not provided outside instead used internally comparing them to external limit voltages. Is there another version of MCT8316 that provides Isense externally or another IC that does similar function with current feedback provided externally?