Tool/software:

DRV8876EVM Board :

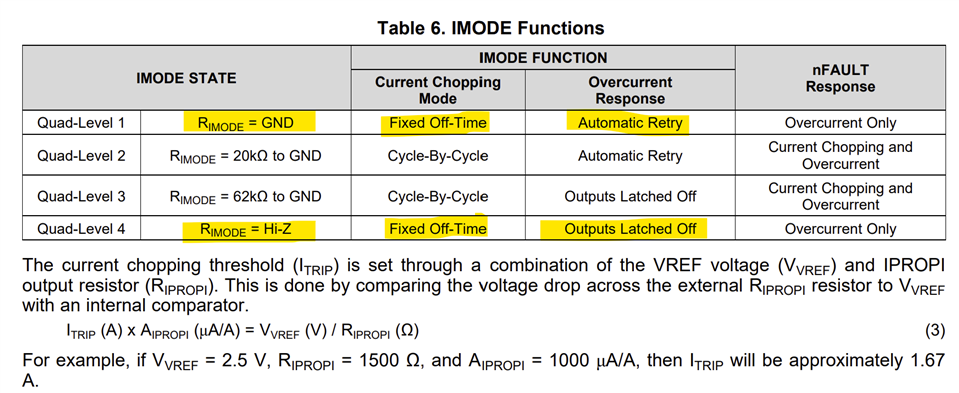

If the motor current is running under normal settings and then suddenly gets stuck, causing the current to increase abnormally, how can we control the external PWM voltage to immediately reduce the current to the limited current value?

For example: set the current limit value to 0.5 A and the operating voltage value to 12V. After the motor is connected, the motor's operating current is 0.2A. Ten seconds later, the motor gets stuck and the current suddenly rises to 3A. How can I reduce 3A to the set 0.5A?