Tool/software:

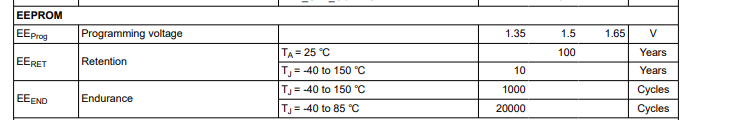

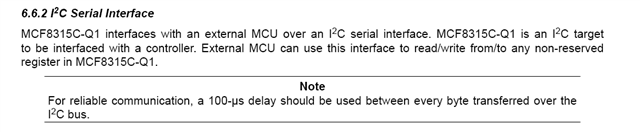

The EERPOM of MCF8315 was flashed with required values and was working correctly. Suddenly it stopped responding over I2C lines (NACK). Also the buck output was configured as 5V in EEPROM, after the issue buck output reverted back to 3.3V.

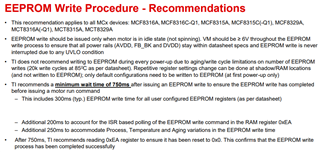

A possible cause can be unintended EEPROM flashing with zeros from the software. But apart from that is there any other scenario where EEPROM values can get reset like this? Since the slave ID was kept as 1, EEPROM reverting to 0 can be the cause of observed NACK as well as buck output reset. Later when communicated using ID as 0, it was responding properly and the EEPROM got re-flashed as well.

I am looking into the possibility of software flashing the EEPROM accidentally with zeros, but it is very unlikely. Please let me know if there are any other possibility of this happening.