Tool/software:

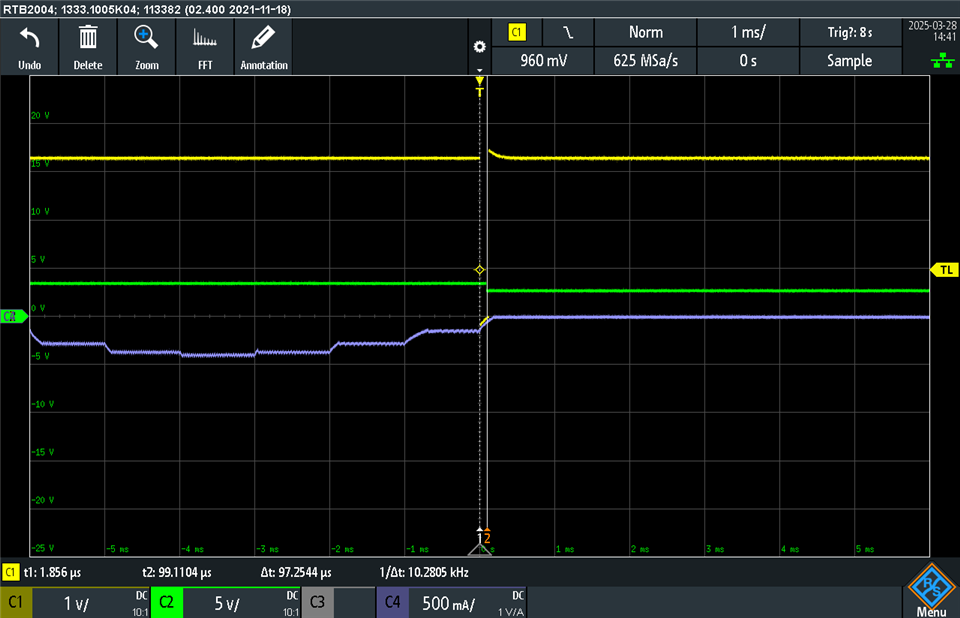

We have custom hardware talking with the DRV8889(latest SI rev of the chip).

We have verified normal operation, by stepping and stalling the motor. Communication packets look good and have been verified.

Open load detection is disabled in our case.

Observation:

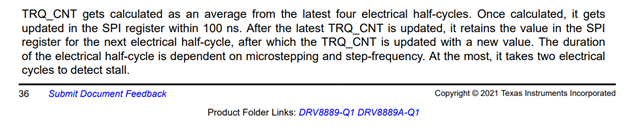

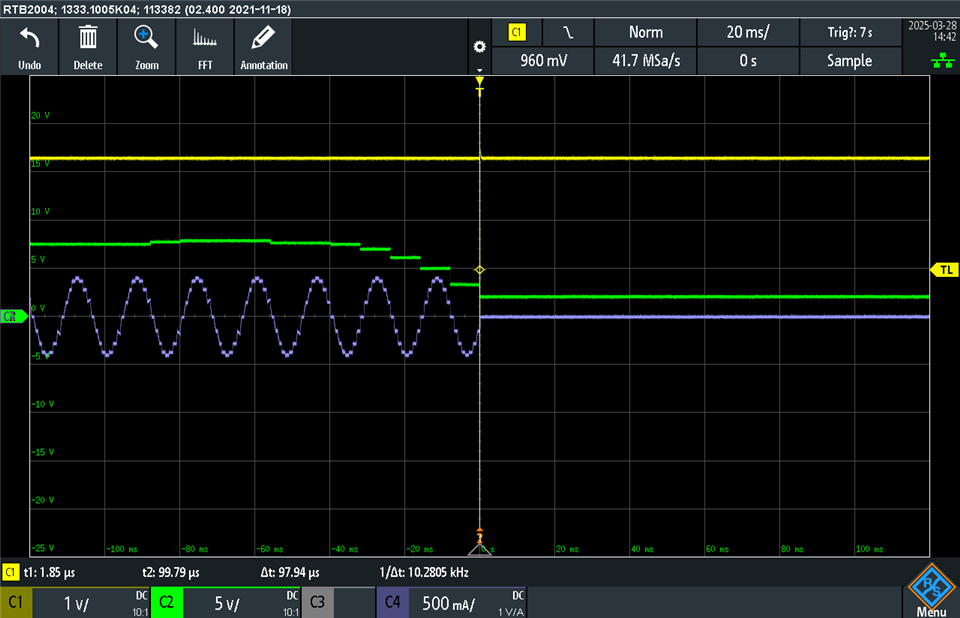

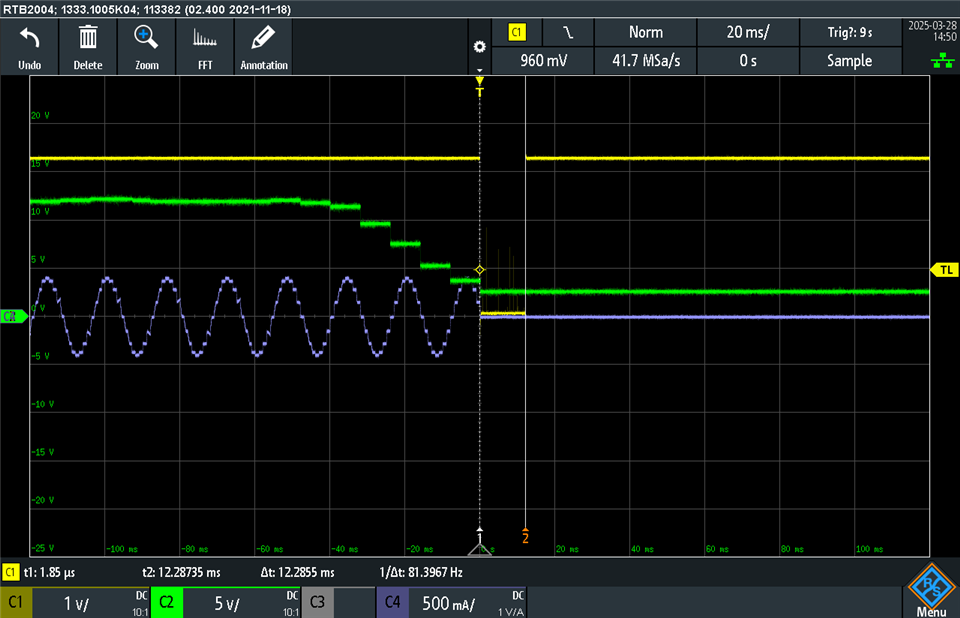

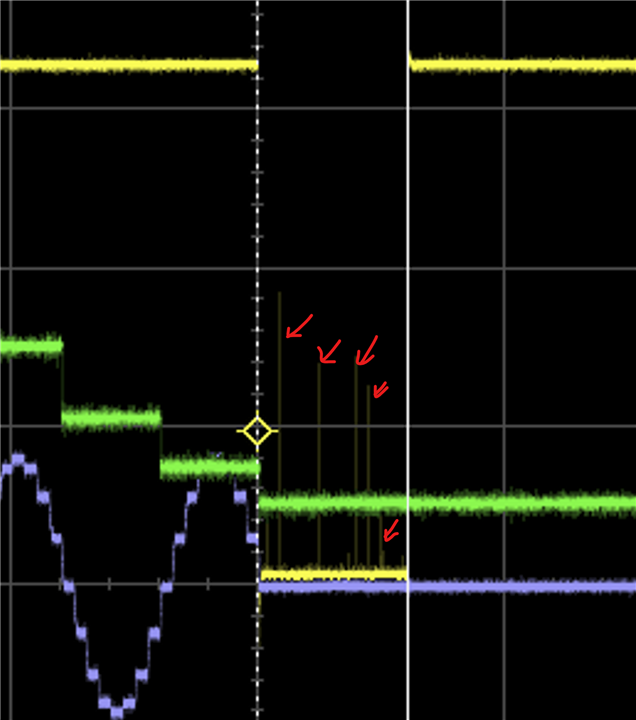

- When a stall condition is detected, it lowers the Faultline, which is an ISR into our host software.

- Host software detects the fault line go low(or high) and send a command to clear the latched faults.

- A readback from the fault status register, 1ms. later, shows the stall bit still set.

- However a clear fault issued again ~250ms later, clears the fault

Question:

Is there a minimum time for the DRV8889 for the stall to clear? Is yes, where is this time specified. If no, how do we calculate this?

Additional info:

The register values we use are below:

FAULT: 0xA5

DIAG1: 0x00

DIAG2: 0x00

CTRL1: 0x83

CTRL2: 0x0F

CTRL3: 0xA4

CTRL4: 0x31

CTRL5: 0x18

CTRL6: 0x0C

CTRL7: 0x00

CTRL8: 0x03