Tool/software:

Hi,

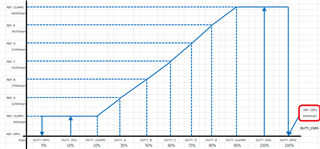

I am currently using the MCT8329A in Linear Mode (REF_PROFILE_CONFIG = 0x01) to implement speed control according to the following conditions:

- 10% to 90% duty cycle → Speed varies from 8000rpm to 66000rpm (linear control).

- Above 90% duty cycle → Speed is fixed at 66000rpm.

I have set REF_OFF2 = 66000rpm instead of 0rpm, but I observed that changing this value does not affect the operation (i.e., whether set to 0x00 (0rpm) or 0xFF (66000rpm), the motor behavior remains unchanged).

Questions & Concerns:

-

Is it correct to set REF_OFF2 to 66000rpm instead of 0rpm in this configuration?

- Given that REF_OFF2 applies when DUTY_CMD ≤ DUTY_OFF2, could it be that my current settings prevent REF_OFF2 from being applied?

-

Current settings for DUTY_ON2 and DUTY_OFF2:

- DUTY_ON2 = 90%

- DUTY_OFF2 = 100%

- REF_OFF2 = 66000rpm

- REF_CLAMP2 = 66000rpm

Issue: Since DUTY_OFF2 is set to 100%, it might not be functioning as expected. Should DUTY_OFF2 be set to a lower value (e.g., 85%) to introduce hysteresis and allow REF_OFF2 to take effect?

-

Recommended Configuration:

- If the goal is for the motor to stop when the duty cycle is below 10%, while maintaining stable operation between 10% and 90%, is the following setting correct?

- DUTY_OFF2 = 85%

- DUTY_ON2 = 90%

- Also, what value should be set for REF_OFF2?

- If the goal is for the motor to stop when the duty cycle is below 10%, while maintaining stable operation between 10% and 90%, is the following setting correct?

I would appreciate your confirmation on whether REF_OFF2 should be set to 0rpm and whether DUTY_OFF2 should be lowered to allow proper hysteresis.

Best regards,

Conor