Other Parts Discussed in Thread: DRV8462

Tool/software:

Hi support team all.

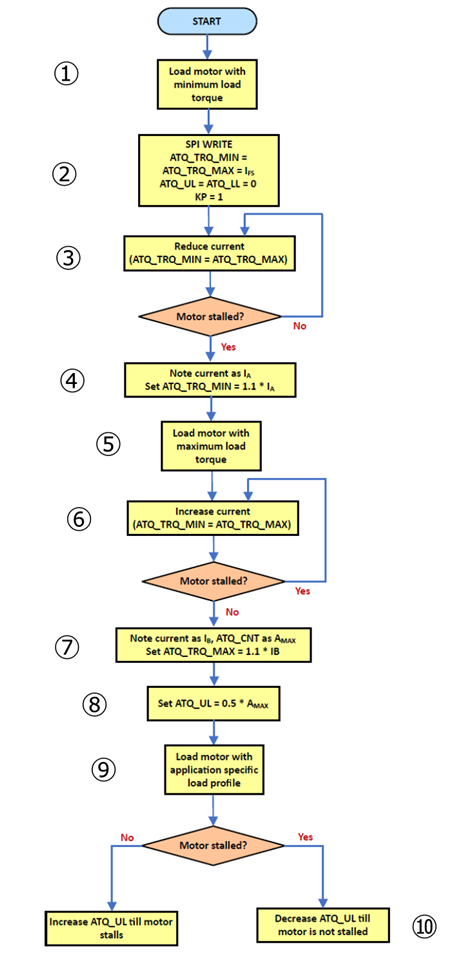

Can you help me set the auto torque for DRV8462?

My customer is testing the auto torque function of DRV8452DDW and is having trouble.

When the auto torque is activated under the following operating conditions, the motor steps out at start-up.

Looking at the current waveform, the current decreases as the motor accelerates, and at about 3A, the motor steps out, probably due to insufficient torque.

I would appreciate some advice on adjusting the auto torque.

<Operating conditions>

Motor voltage: 42V

IFS: 4.2A

STEP frequency: 160000pps

Microstep: 1/32

Other settings: Please refer to the attached csv file.

Please let me know if there is any information missing.

Best regards,