Other Parts Discussed in Thread: BQ25892

Tool/software:

Greetings to all.

Sorry for the delay, but the new boards have finally arrived, and I was able to test them. I see that the original post has been blocked, so I'm creatings this related question. I don't know if I need to re-write the context, please let me know if it's needed. First I'll comment what changes I did to the board, and then the results of the tests.

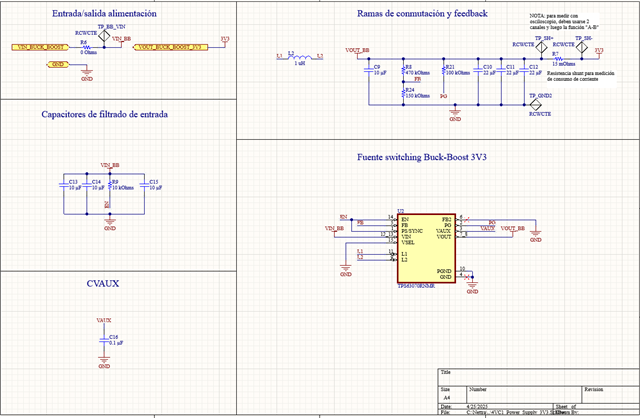

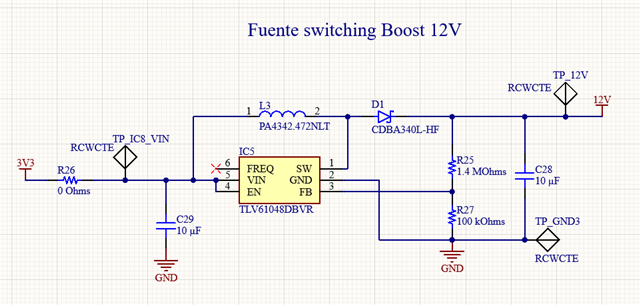

Regarding the changes, what I did is change the 12 VDC power supply. I chose the TLV61048DBVR from TI, which has a peak switching current limit in between 2.9 and 4.5 A:

![]()

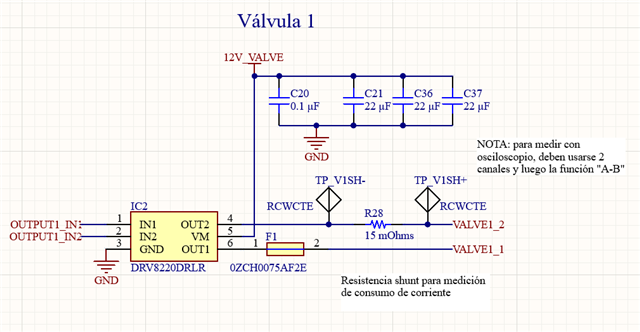

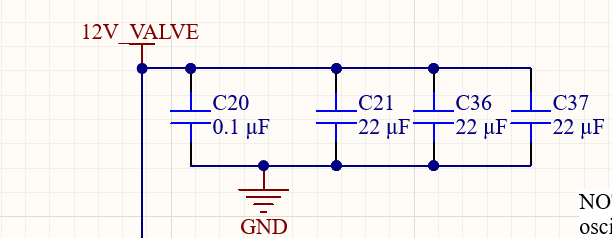

In addition, as Jacob suggested, I added a series of capacitors to each output, for a total value of 66 uF:

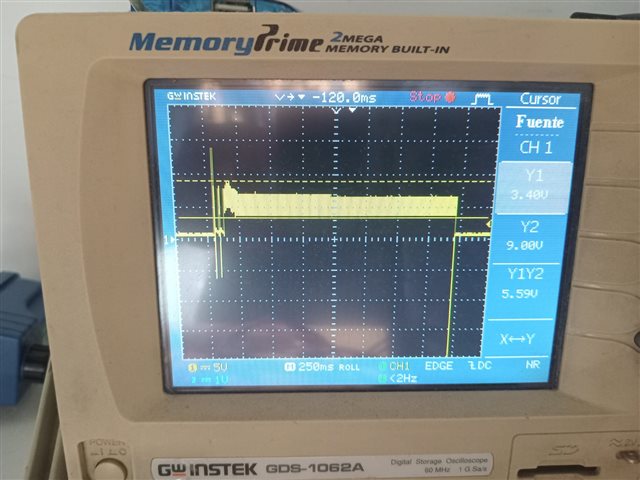

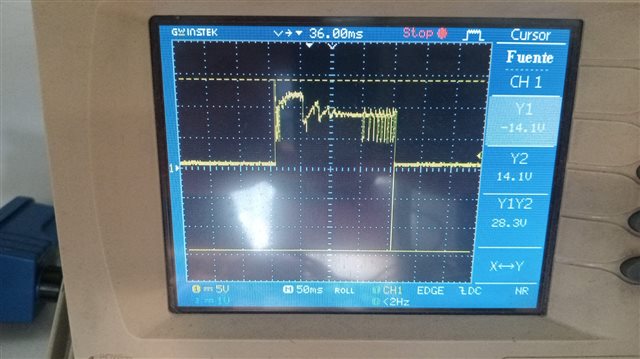

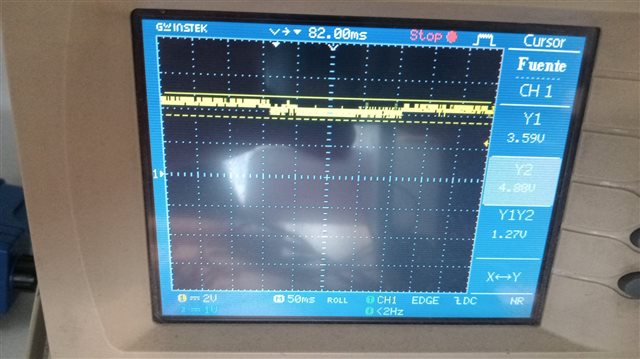

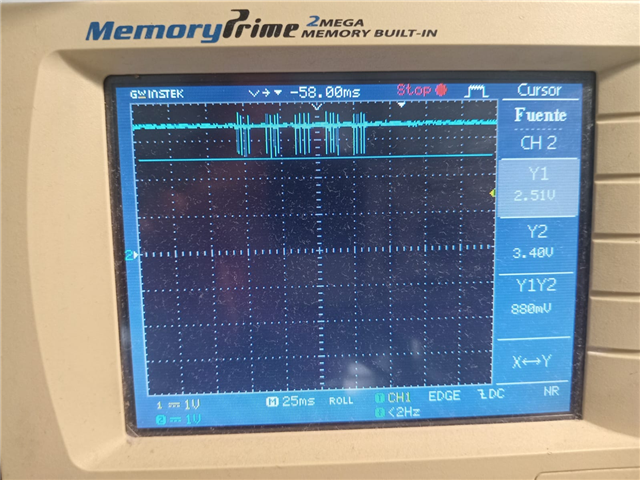

Now, regarding the results, sadly, they remain the same. The ESP32 still resets. I was able to see the voltage drop in the 3V3 line when the valve is triggered:

As you can see, the voltage drops below 1V.

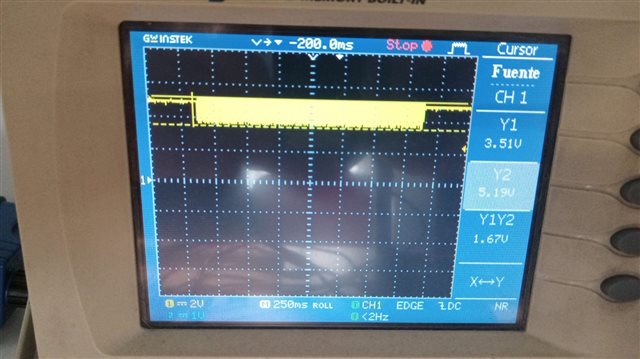

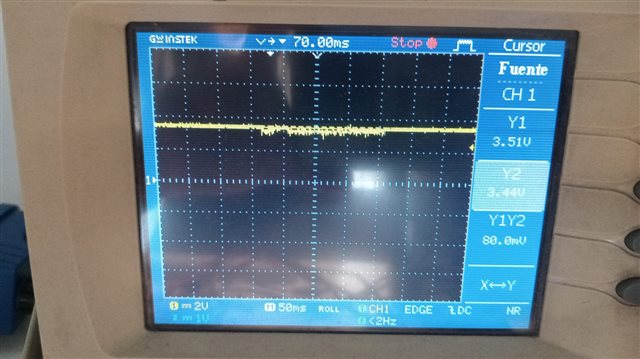

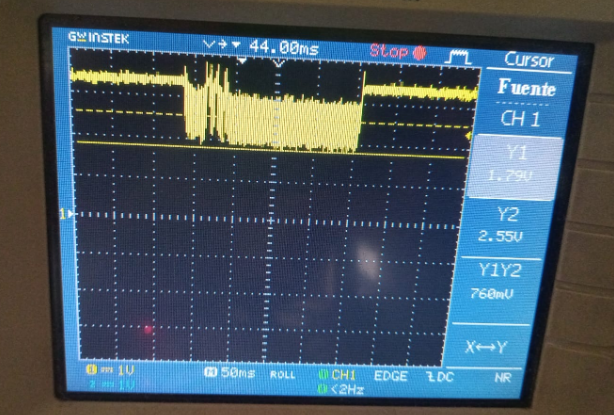

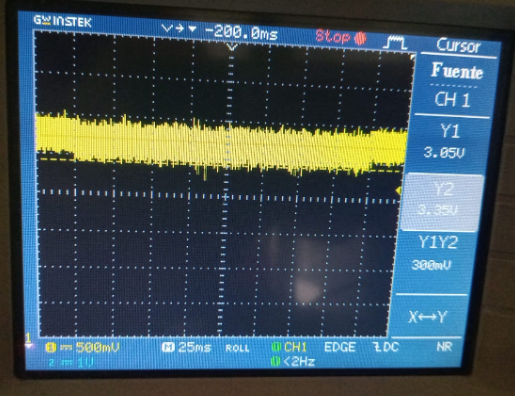

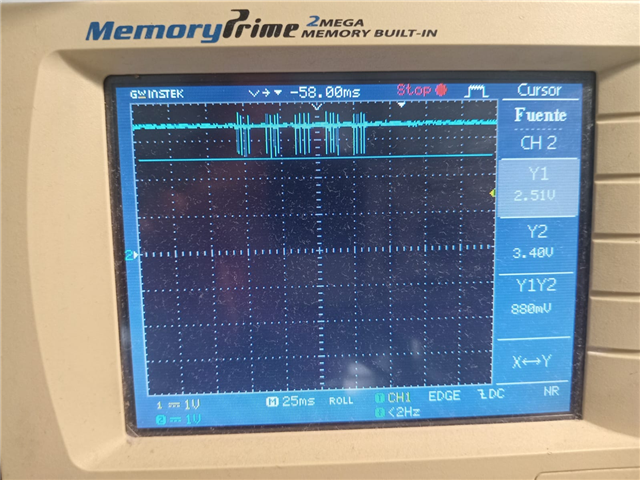

Then, what I did Is try to isolate each power supply, so I could find which one is failing. First, I powered the board with 4V between the output of the battery charger and the input of the 3V3 power supply, and tried to trigger the valve. And with that test, the valve was able to open without causing the ESP32 to reset. This is what I saw in the 3V3 line:

As you can see, although there's a voltage drop of around 500 mV, it doesn't drop below 1V as before.

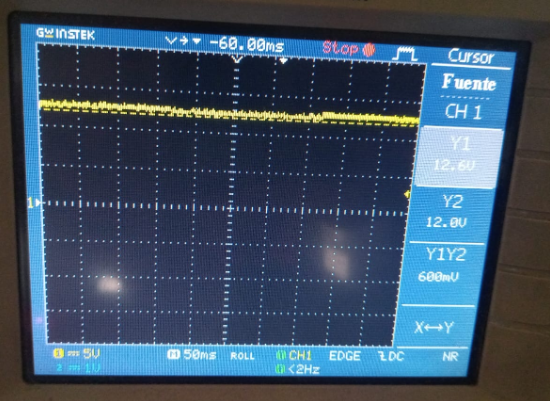

What I get from this test is that the problem should be in the battery charger IC, which is the BQ25892 from TI. But the things is that that IC, at least according to its datasheet, can support of to 5A of switching current, a value well above the one that the valve requires to switch. I know that that IC has some current and voltage configurations, such as the maximum allowed switching current, but I've checked those values, and the ILIM current is set to 3.25 A, and the VREG voltage is set to 4.208 V, so I would say that that's not the problem.

Any ideas of what could be wrong? Thank you.