Tool/software:

Hi there,

I am currently troubleshooting a custom implementation of DRV2700 based on DRV2700EVM-HV500. My design is implemented almost exactly as per the reference design, aside from a few key differences:

- I am using a custom wound flyback transformer based on ETD29 core with 0.9 mm gap. The primary winding is 15 turns, and the secondary is formed from 4 x 93 turn windings, wired in series, for a total input:output turns ratio of 1:25.

- Each secondary winding has an S8CMHQ flyback diode and 10 nF 3 kV ceramic capacitor.

- I've measured the primary inductance at 19.5 uH

- I am using a higher voltage rated MOSFET than the EVM - IXTA02N250HV.

- My feedback resistors are: 20 MegOhm, 1 kOhm and 10 kOhm.

- My lower feedback resistor is driven by an opamp betwenn 0 and 1.3 V to adjust the HV output between 0 and ~2 kV.

When I try and drive the output voltage beyond 1 kV, I find that the voltage on the FB pin sags, and the output voltage no longer increases. I noticed that when probing the switch pin with the PWM duty cycle set beyond ~ 55 (beyond the duty point that causes V_FB to sag), the DRV2700 appears to be driving the controller at around 90 % duty cycle. Have I reached the limitations of what the IC can do here?

The first two screenshots are with my PWM duty configured such that an output voltage of 650 V is developed. The converter is operating in a mode where a burst of pulses appear at the SW node (channel 3). The output voltage is shown on channel 1. The second screenshot is a close up of the switching event.The duty cycle is around 90 %.

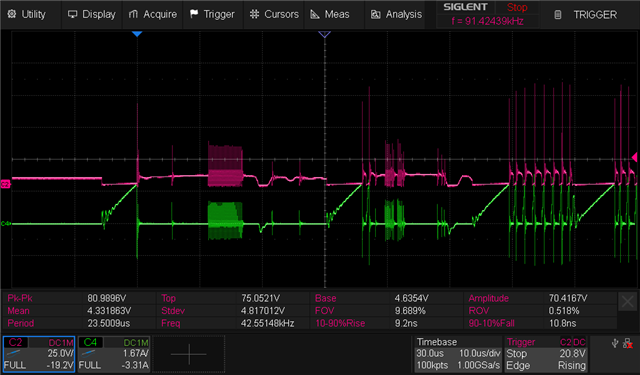

The next two screenshots are when I increase the PWM duty beyond 55 (50 in this case), which is at the point where the output voltage no longer increases, and the FB pin voltage sags. The output voltage is much steadier, at around 1 kV, and the SW node looks very similar. The difference with this mode is that there is no pulse skipping, the SW node is constantly switching at around 90 % duty:

Currently the output is loaded with around 13 MOhms of resistance, plus a MICSIG isolated differential oscilloscope probe DP3002 (rated for 3 kV). There is also 10 nF of bypass capacitance, at the output. The REXT value is set at 6 kOhm (the minimum recommended value).

Thanks in advance for your help.