Other Parts Discussed in Thread: DRV10983

Tool/software:

Dear TI experts,

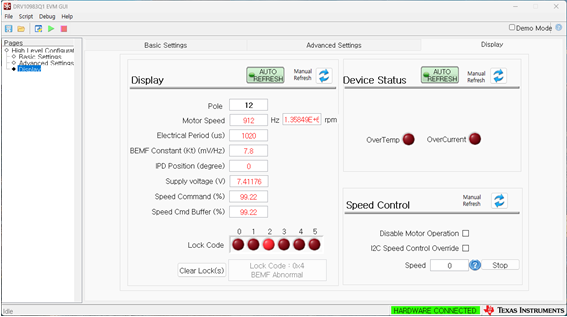

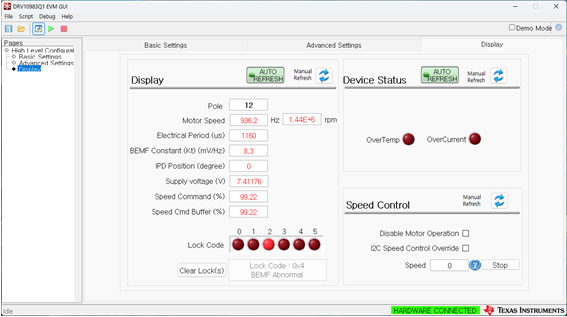

My customer is looking for parameters about restart, but I cannot find it in GUI.

The problem is, if customer stops spinning the motor by his hand, the motor spins at low speed.

(Customer expected that spinning at same speed after stop by hand.)

Could you check that this is normal operation? and also check the parameters about restart in GUI.

I attach the video clip about stopping motor assembly which my customer did.

Please check this issue. Thanks.

Best regards,

Chase