Other Parts Discussed in Thread: DRV8316

Tool/software:

Hi team,

I am using the instaSPIN-FOC GUI for the motor identification function with two motors. One has 7 pole pairs, and when the GUI runs the motor identification algorithm, the motor power consumption reaches 20W and overheats severely. Another motor with 8 pole pairs,the motor identification algorithm runs successfully and the GUI shows "motor identified", but when I click RUN, the motor only vibrates once and does not spin.

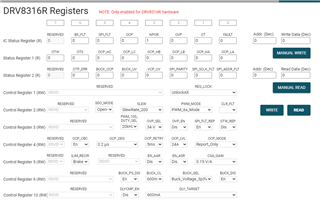

Does the motor identification algorithm have specific requirements for the parameters of the motor?The following image and video are the motor with PP of 8.