Other Parts Discussed in Thread: DRV8353

Tool/software:

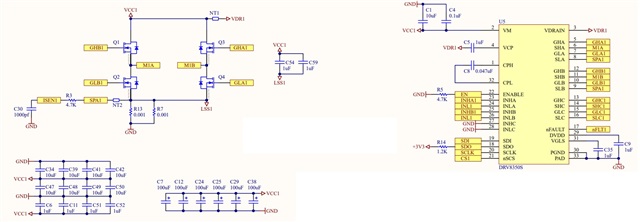

I am testing a new design. It is a near copy of the evaluation design for the DRV8353. Initial testing was throwing a Gate Driver Fault(no damage) on HA or HB depending on how PWM was started. My reading of that error was that the mosfets were not turning on fast enough with such low gate current(started at 50ma/100ma. I started increasing the gate current. Same fault each time until I got to around 600ma/1200ma. Then I would get a FAULT bit set(nothing else in FSR1) and a GDUV fault on FSR2. At this point the chip starts over heating and pulls 100+ ma at all times(even after a hardware reset without enabling the driver). The chip is obviously damaged at this point. This has happened multiple times and I have been unable to determine the cause.

I am driving fairly large mosfets. HYG016N10NS1TA

Gd is 47 nC

Using capacitors as spec'd in the datasheet. This happens at VM 15v up to 60v(have not tested below 15v though the design should work down to 6.5v). Original design used MIC4102 gate drivers(in a shipping design) but those don't have all the protections the DRV has.

We are not driving a motor yet. No load is attacked of ANY kind. This is happen simply trying to drive the mosfets.

No excessive current happens UNTIL the driver is already damaged(getting the FAULT/GDUV flags).

SHC and SLC are grounded(we are not using that port since this is for a Brushed motor). Grounding only SHC did not remove the PortC fault. Grounding SLC prevented that error.

Schematic is attached and all filter caps(not bulk caps) are within 1 to 2mm of the DRV respective pins.

trace width is the same as (but shorter distances) compared to the EVM so I don't see inductance on the traces being the cause of this.

Any help would be appreciated.