Other Parts Discussed in Thread: , DRV8263-Q1

Tool/software:

Hello,

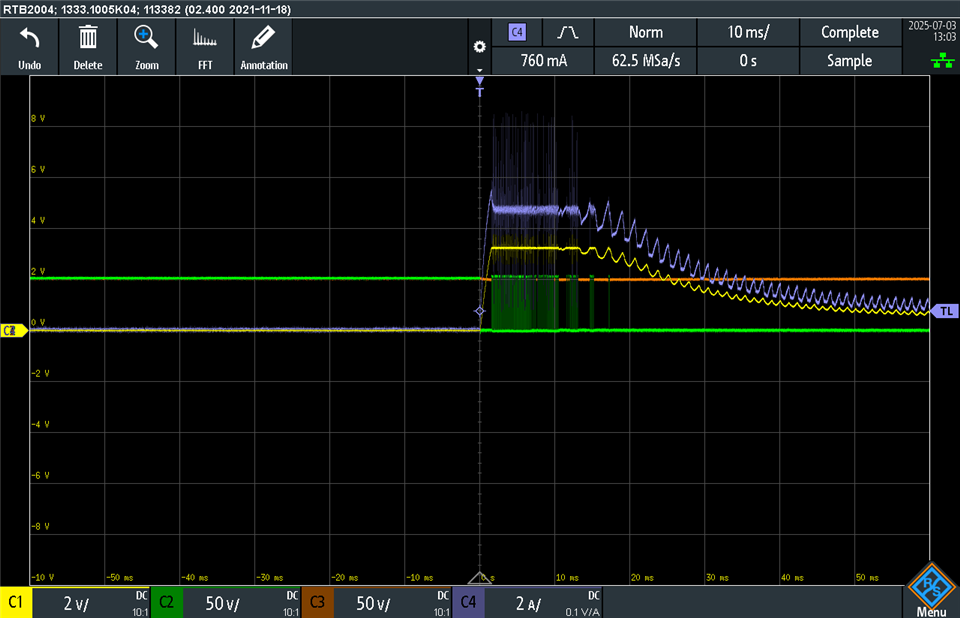

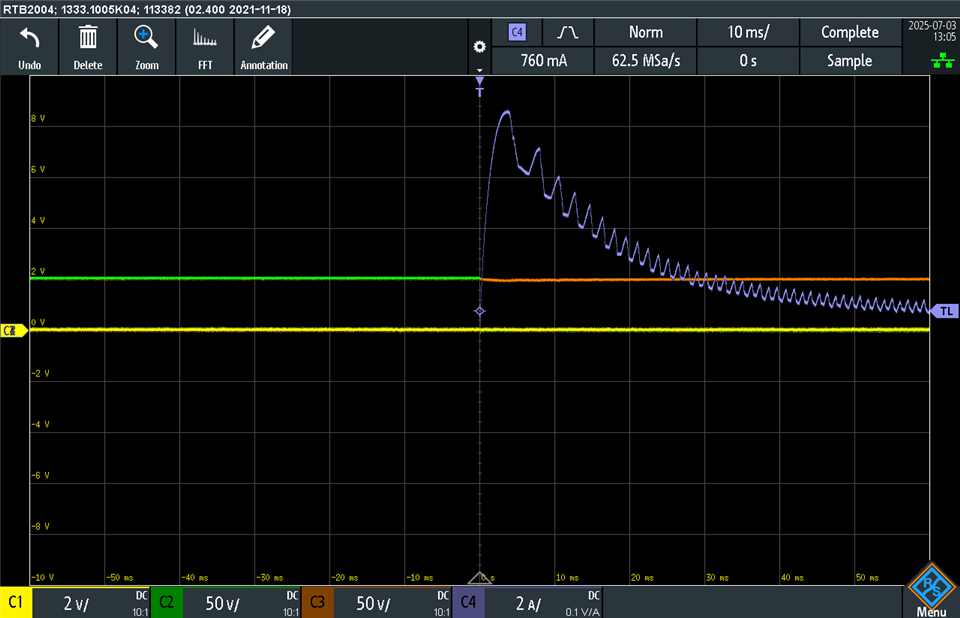

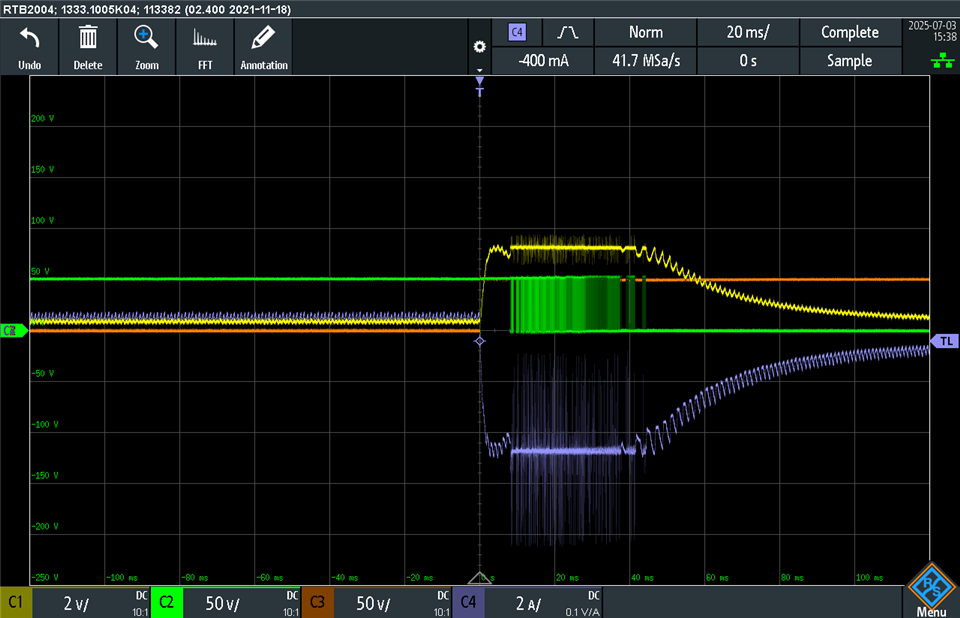

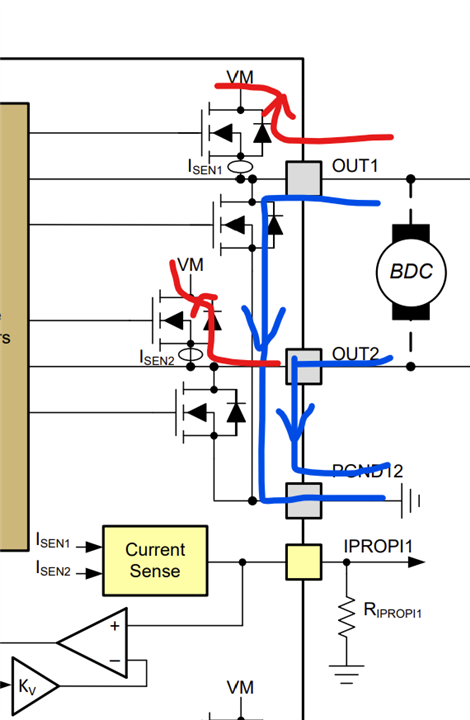

I am trying to use DRV8262 for brushed DC motor application with single H-bridge.

My motor will run at DC (not PWM) with VM voltage of 35V and motor current about 3A. Depending on enable signals of DRV8262, motor will stop/forward/reverse, but all DC.

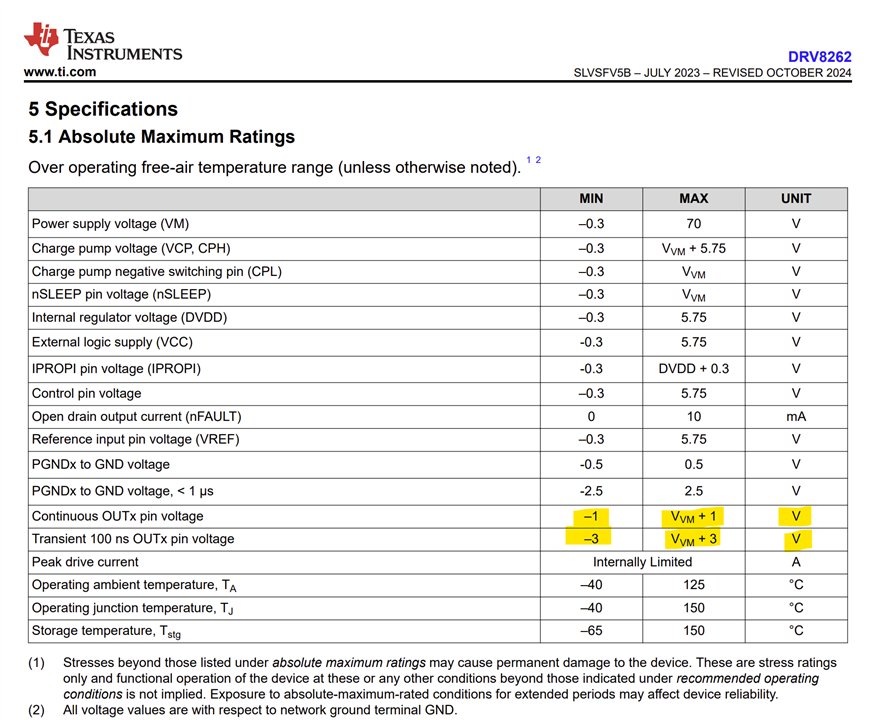

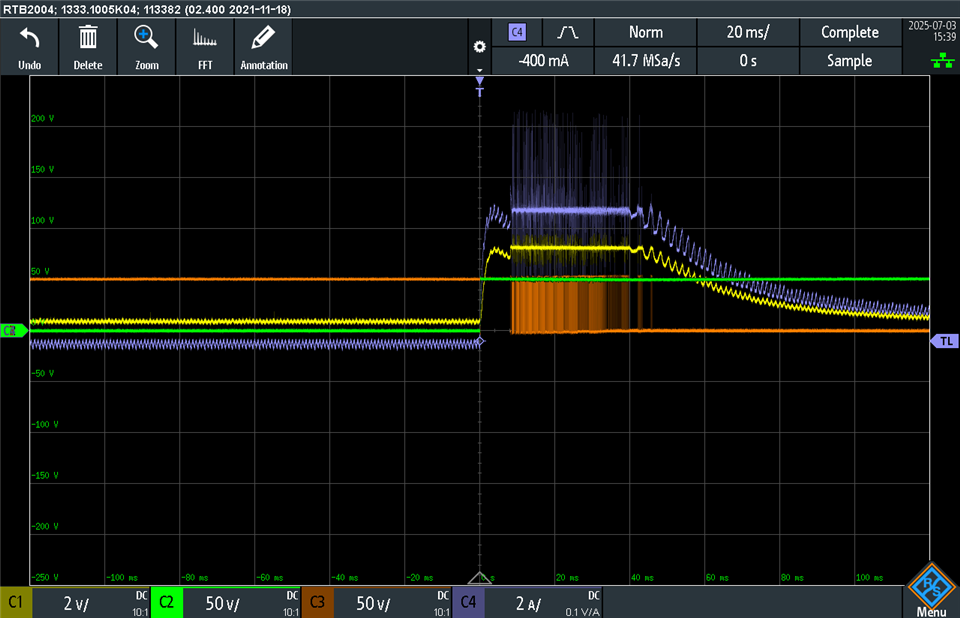

I don't see any Back EMF mitigation electronics in the DRV8262EVM. Do you have any suggestion as to which electronics need to be included to suppress BEMF in addition to what EVM has? I don't see DRV8262 itself regulating Back EMF.. I don't have good number of what BEMF voltage will be and I really need to test it out in the lab. Not sure if it's safe to use DRV8262 to drive the motor with above spec. It would be great if anyone can confirm. Basically, I am not sure if I need to include additional circuits (i.e., back emf shunt regulator or regen resistor) not to damage DRV8262EVM. I would also need to know when it comes to the custom design.

Please let me know if you need additional information from my side. Thank you!