Tool/software:

Hi again,

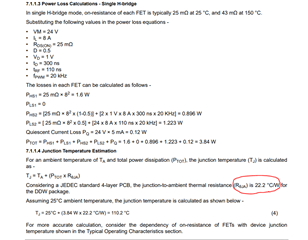

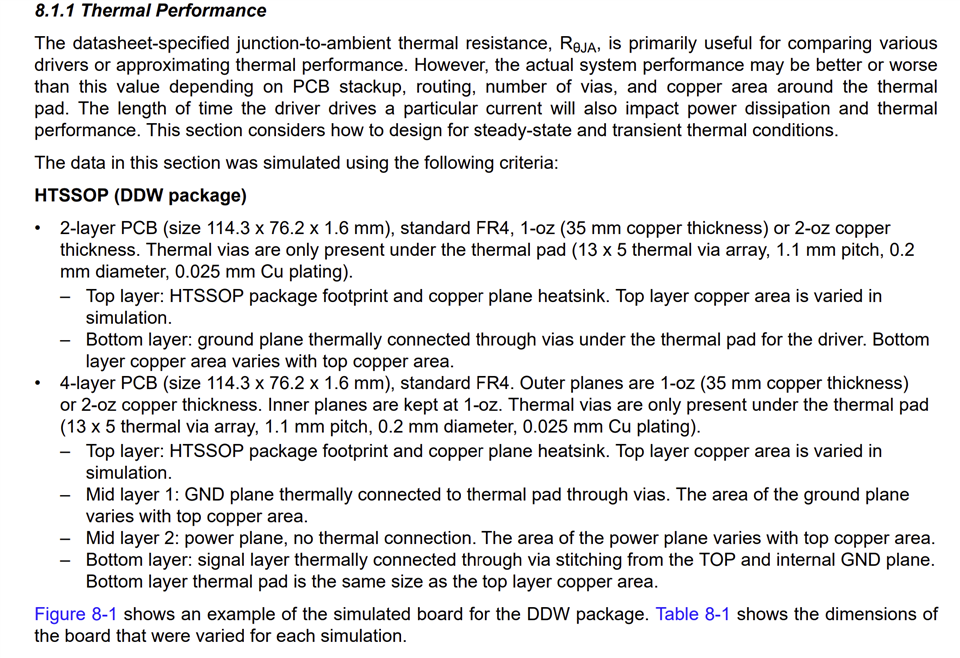

In DRV8262 datasheet, when power loss is calculated in the example below, it mentions that they use 22.2 C/W as Rja considering a JEDEC standard 4 layer PCB.

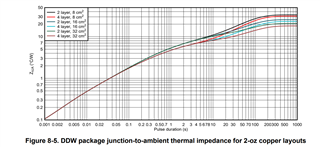

It seems that the example shown there is PWM signals. Why do they use DC parameter of Rja in this case? Shouldn't I look into thermal impedance plot over duty cycle? In the example, duty cycle is 0.5 and frequency is 20kHz, so looking at the thermal impedance plot at 0.025ms (0.05ms/2) gives me much lower Rja. I wanted to clarify why 22.2C/W is used instead. It seems that 22.2C/W is Rja at DC operation.