Tool/software:

Dear team,

Would you please help me to understand below queries?

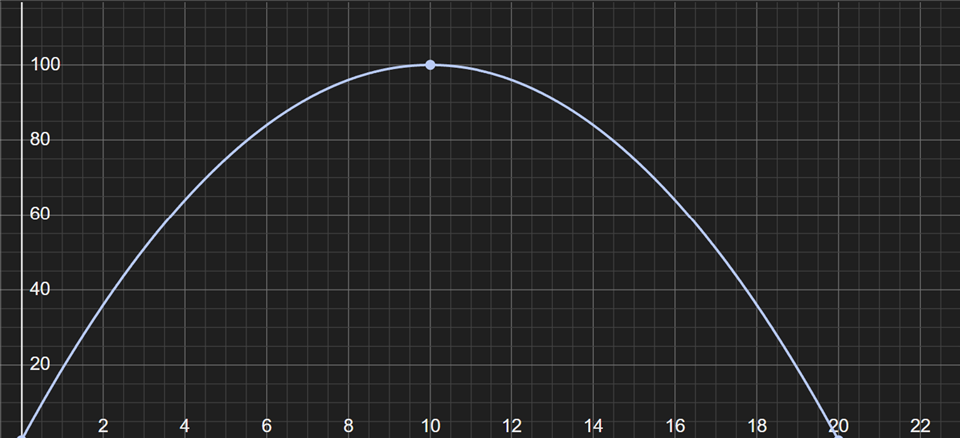

1. I learned we need to change STALL_TH when we change the motor speed. In general, which should it be changed to increase or decrease the STALL_TH when speed-up.

2. On EVM, we can adjust the motor speed(pps) and acceleration rate(pps/s). It should be MCU processing issue, but on EVM how much is the time-wise resolution of acceleration rate?

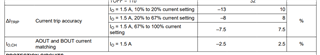

3. Does IC or ambient temperature affect to output current accuracy? In other words, can we understand below specification is for all temperature range or only room temp?

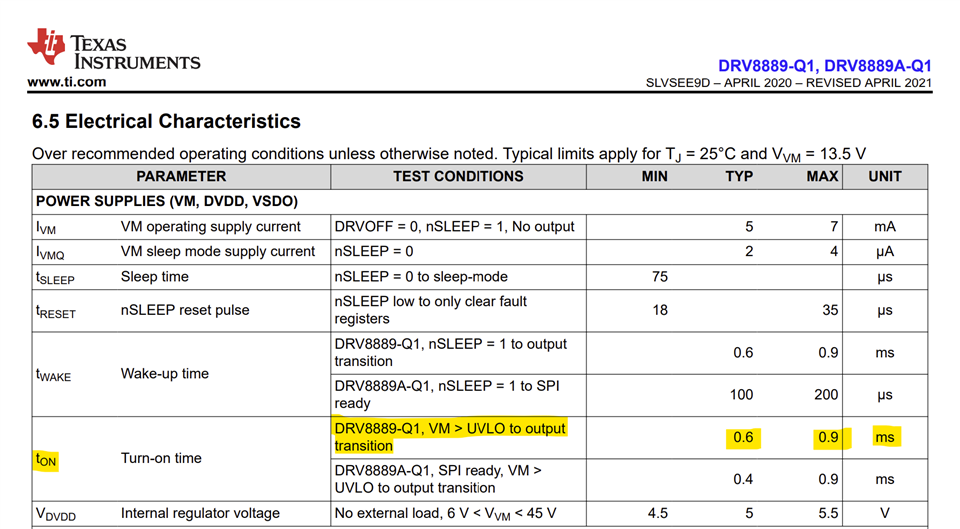

4. How long does it take to be ready to operate normally after VM is greater than 4.5V?

Best regards,

Yuto