Other Parts Discussed in Thread: DRV2901, DRV2911-Q1, ULC1001-DRV290XEVM, ULC1001-DRV2911EVM, DRV2911, ULC1001

Tool/software:

Dear TI experts,

My customer considers ULC1001-Q1. They are planning to make automotive camera with ULC1001-Q1.

Unfortunately I do not have full datasheet of ULC1001-Q1 so I cannot check many information. Could you check the questions below?

1. Could you recommend any piezo parts which performance is verified with ULC1001-Q1? (any vendor, any part number including Murata and TDK and so on)

2. What is the maximum and minimum size of piezo parts?

3. What is the difference between DRV2901 and DRV2911-Q1? Cause DRV2911-Q1 is automotive qualified and have better shutdown parameter but it is cheaper.

3-1. Do you have any plan to release automotive version of DRV2901?

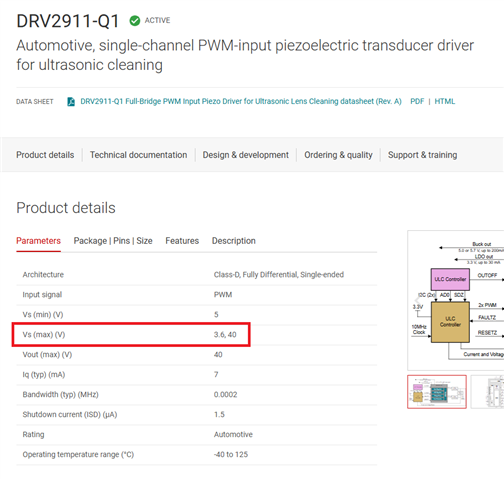

3-2. What is the meaning of Vs(max)(V) = 3.6, 40 in DRV2911-Q1 parameters? Why does it have 2 parameters?

3-3. the difference between ULC1001-DRV290XEVM and ULC1001-DRV2911EVM is only the difference of piezoelectric transducer driver? Rest of EVM are same?

4. I can see optional LC filter parts in the datasheet of DRV2911-Q1, figure 7.2.

the values of these LC filters are fixed values which depends on the piezo parts? or Can I change it for better performance?

If I can change, Can I get more information about it? (Equation, or other information)

Also i want to know the values about pullups and pulldowns to ISNS_x and VSNS_x.(R1~R6)

5. Could you check essential Vin for the system? My customer saw 35V and also 12V in old datasheet.

6. What is the maximum output power(W) from DRV2911-Q1 or DRV2901?

7. What is the data format of output of DRV2911-Q1 or DRV2901? (PWM, sine wave, or etc)

8. My customer wants to use 3 ultracleaning systems in one MCU. Is it possible to control separately through I2C?

9. About calculation tool, Should my customer calibrate every single modules for better performance? or Can I use only one set of parameters for every modules?

10. Do you have any standards about thickness and hardness of piezo parts?

Please check these issues. Thanks.

Best regards,

Chase